Commercial Vehicle Products | Air Springs

Bionics

Offer high comfort and robustness while reducing weight and costs

Offer high comfort and robustness while reducing weight and costs

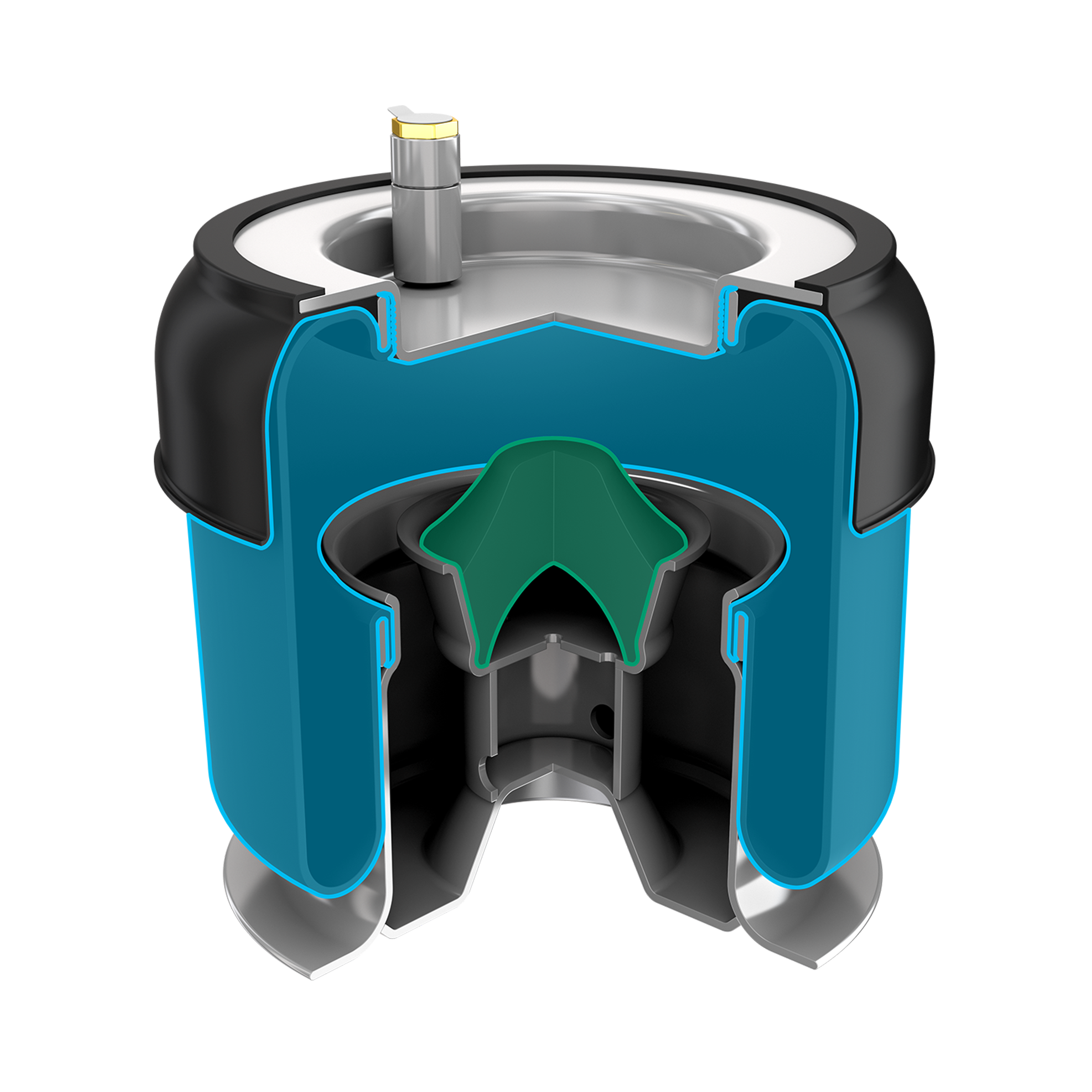

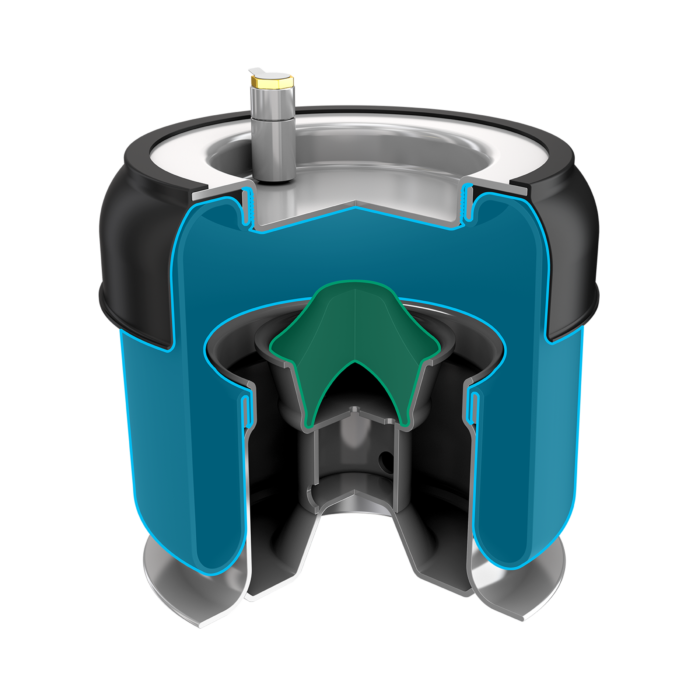

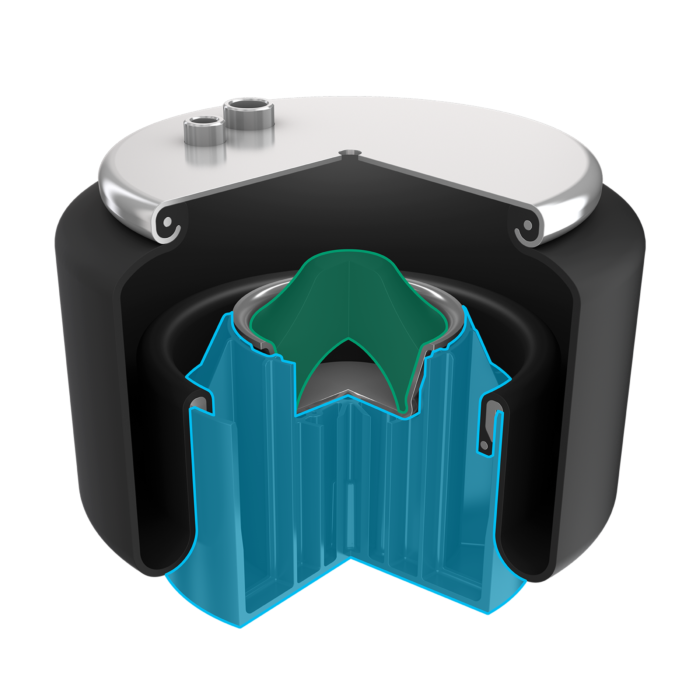

Bionics are the first sleeve-type air springs for commercial vehicles and are much smaller compared to traditional air spring assemblies. Vibracoustic engineers have successfully transferred the concept of sleeve-type air springs for light vehicles to the much more demanding application in commercial vehicles with the unique Bionics air springs.

The compact design allows them to fit directly under the vehicle frame without the need for additional mounting assemblies and enable a larger steering angle resulting in a smaller turning circle. Eliminating heavy and expensive bracketry and screws results in high cost-efficiency for truck manufacturers and leads to weight savings of more than 70 kilograms. The result is an overall increase of the payload and higher fuel-efficiency with less CO2 emissions. Other benefits of the reduced complexity of the assembly are increased service intervals, higher durability and reliability.

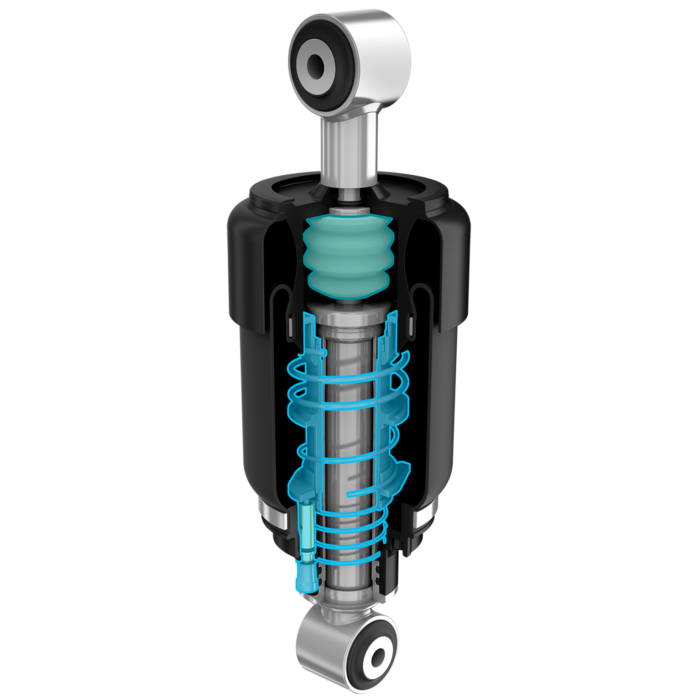

Compared to a standard rolling lobe air spring, Bionics have a reduced height while offering the same spring travel. The innovative design of the double fold crimped sleeve and thin bellow walls made of a special, heat resistant rubber compound result in quicker and smoother response to road and driving conditions. In combination with the high-comfort bump stop with excellent emergency running properties, this commercial vehicle air spring offers an extended lift range as well as optimized suspension and driving comfort.

Another benefit of this innovative air spring solution is the load capacity. The special design allows an air pressure of 8.8 bar able to carry axle loads of eight tons. Vibracoustic engineers have already achieved a nine-ton load capacity with Bionics air springs and even higher loads can be achieved with this solution.

With Bionics, Vibracoustic also offers a modular concept: the same spring housing can be used across a range of models regardless of frame height and spring characteristics, reducing logistics and material costs for commercial vehicle manufacturers. With the unique “push-on” mounting system, Bionics enable a tool-free, easy assembly and provide additional cost benefits for truck manufacturers and customers. After the end of their lifetime, Bionics sleeve-type air springs can be separated into one-type materials, offering recycling benefits and sustainability.

About Air Springs

From the minimum loads of an unhitched tractor to the weight of a fully-loaded trailer, commercial vehicle axles need to cover extreme load fluctuations with the rear axles being exposed to the main load of those fluctuations. With their ability to quickly change the spring rate according to the current load situation, commercial vehicle air springs are an excellent solution for this challenge. Therefore, they are used in most commercial vehicles like trucks and buses as well as in trailers.

more

Commercial vehicle air springs from Vibracoustic CV Air Springs offer an excellent combination of reliability, safety, and comfort for trucks, tractors, trailers and buses. By adding or releasing air, the same level of driving comfort can be provided and a constant height can be maintained for all load situations.

Keeping the vehicle and trailer at a constant height level maintains vehicle stability and provides safe driving characteristics. Furthermore, it improves vibration damping in all load conditions. This reduces axle, transmission and tire wear and increases vehicle durability and efficiency. In addition, the truck suspension cannot bottom out thanks to the air springs and the chassis and the transported goods are strongly protected from damage.

The driver as well benefits from improved vibration damping, which provides high driving comfort and reduces driver fatigue for a relaxed and secure haulage.