Light Vehicle Products | Motor Mounts

Hydro Motor Mounts

Combine acoustic isolation with balanced damping performance

Combine acoustic isolation with balanced damping performance

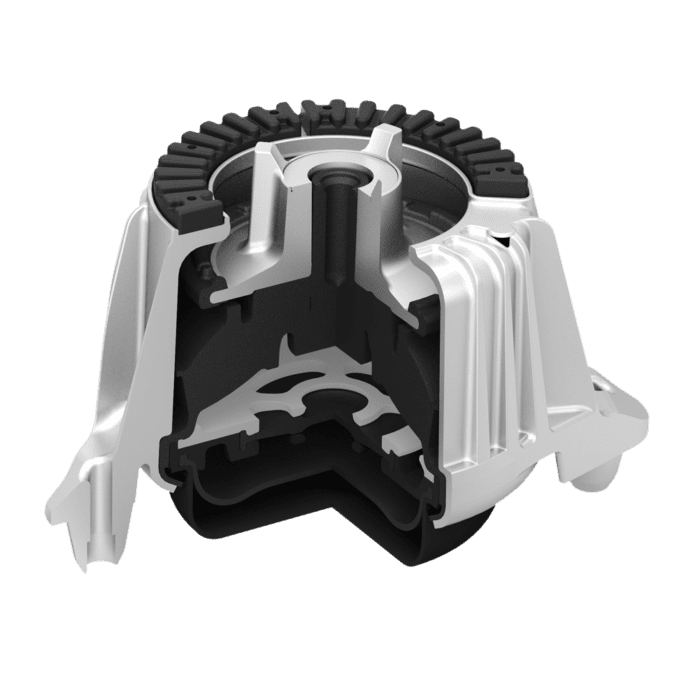

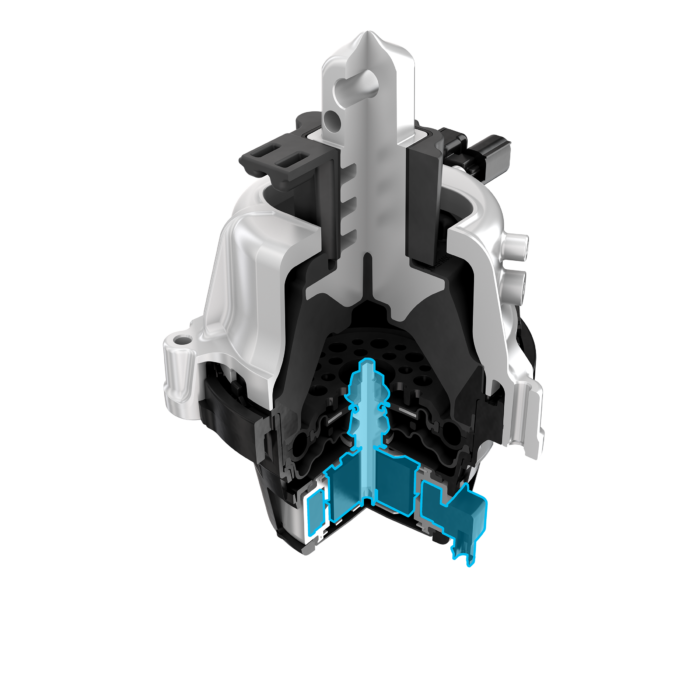

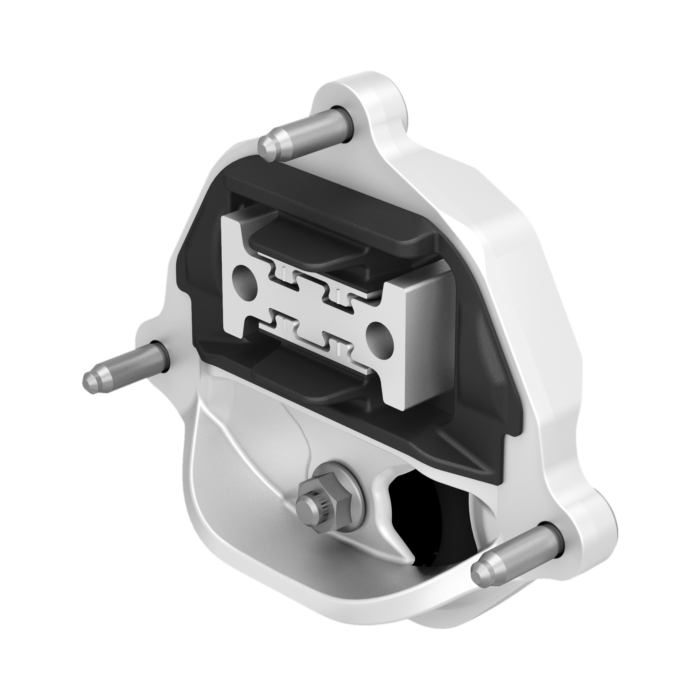

A hydro motor mount has an upper and lower chamber connected by a series of channels and separated by a rubber membrane inside a cage. The mount is filled with hydraulic fluid, which generates secondary damping.

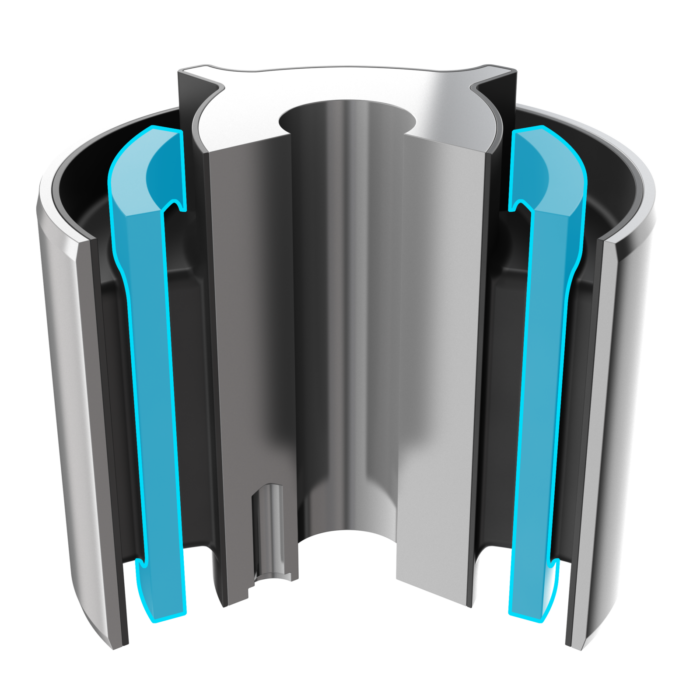

At small idle amplitudes, the rubber membrane of the passive amplitude decoupler easily moves up and down, allowing the mount to remain very soft. At larger road shake amplitudes, the cage stops the decoupler motion, thus redirecting the fluid flow to the main channel in order to create hydraulic damping for a comfortable ride. To optimize the function and tunability of the mount to suit varying customer demands, complex hole patterns for the membrane-holding grid as well as fluid channel geometries can be developed and applied.

A vertical stopper made of thermoplastic elastomer with a corrugated surface for smooth and quiet engagement prevents metal to metal contact at maximum impacts. Lightweight aluminum housings further reduce weight and increase overall efficiency.

Motor mounts control engine movement in all directions, thereby achieving excellent driving comfort and driving dynamics without compromising performance.

About Motor Mounts

Motor mounts carry the static and dynamic loads of the motor throughout its entire service life and are also an important factor for isolating low to high frequency vibrations. Downsized and turbocharged motors are state-of-the-art to reduce fuel consumption but lead to high vibration levels.

more

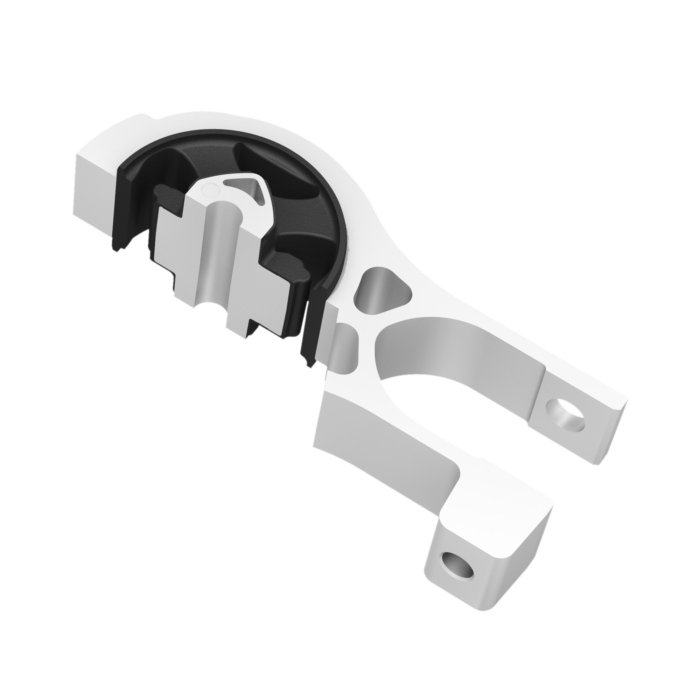

Motor and transmission mounts consist of a motor or gearbox support arm, an isolation element and a body-side connecting element. The critical element is the rubber spring that dampens vibrations, supports drive torques and isolates noise during start-up. The motor mount prevents booming noises and load-change shocks. Vibrations of the body and drive train are improved by using a hydraulic damping system. Motor mounts effectively isolate motor vibrations and dampen road excitations to ensure a comfortable driving experience.

The product portfolio ranges from conventional rubber mounts and hydro motor mounts, through electrically or pneumatically switchable motor mounts, to gearbox mounts and torque rods.