Light Vehicle Products | Centering Devices, Isolators & Dampers | Power Train

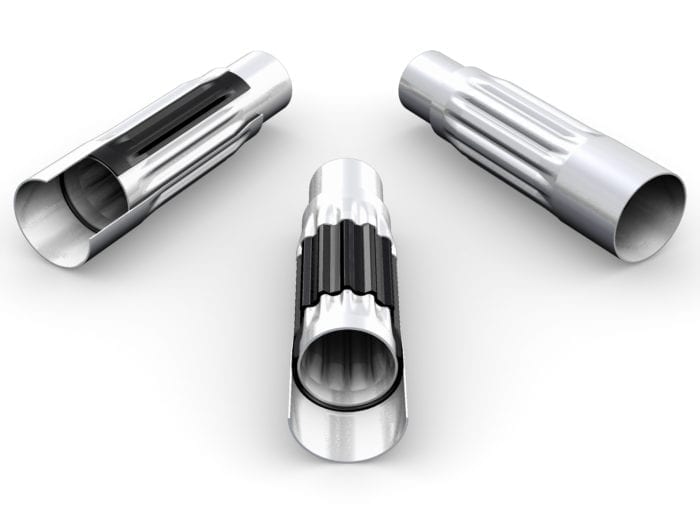

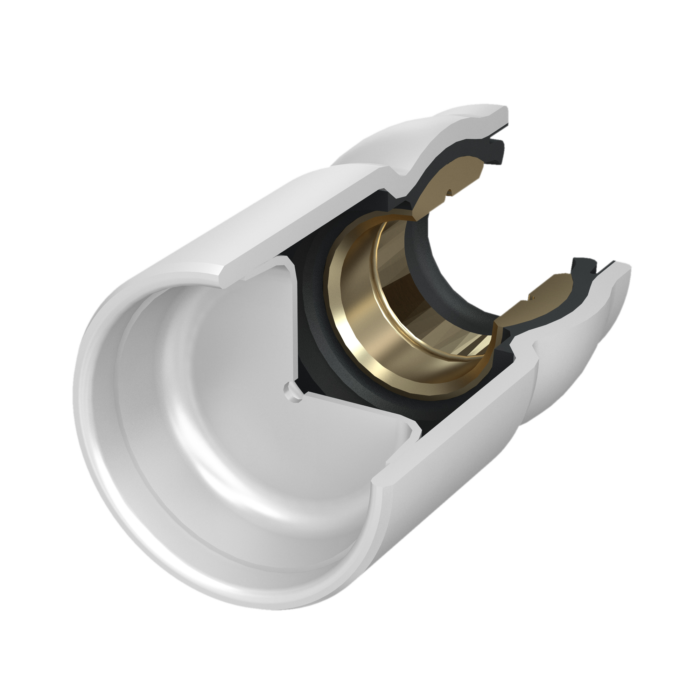

Tube-in-Tube Torsional Isolators

Reduce effects of torsional vibrations of the drive shaft, offer compact design for tight installation spaces

Reduce effects of torsional vibrations of the drive shaft, offer compact design for tight installation spaces

The shape is created through the rotary swaging of a tube. The drive shaft is installed between the transmission and rear differential unit, above the exhaust system and catalytic converters that radiate extreme heat. Elastomeric applications must be able to withstand ever-higher temperatures.

Thanks to tunable damping rates, the design of the coupling offers reduced vibrations for comfortable rides, especially in higher gears. An optimized rubber compound can further improve isolation.

The Tube-in-Tube system is a cost-effective and flexible solution to the conflicting objectives of high thermal stability, durability, and damping. Owing to its special design, the Tube-in-Tube system can also serve as an additional crash feature.

About Centering Devices, Isolators & Dampers | Power Train

Centering devices, isolators and dampers solve vibration-related challenges deriving from the torque fluctuations and natural frequencies of the drive shaft in rear- and all-wheel drive vehicles, where the drive force must be transferred to the rear axle. Rotary dampers, flexible couplings and centering devices help counteract unwanted noise and vibrations from the drive shaft.

more

Our product portfolio includes flexible power train couplings and damping devices like the NRG-Disc (New Rubber Generation Disc), Tube-in-Tube or Drive Shaft Dampers. They smoothly transfer drive forces to the rear axle and reduce vibrations deriving from the torque fluctuations and natural frequencies of the drive shaft.

In addition to elastic decoupling elements, rotation dampers can be used to effectively reduce system-related resonance effects of the drive shaft.

Center Sleeves, Spherical Center Sleeves and Center Bearing Supports help align the drive shaft and allow flexible movements of the drive shaft while being constantly exposed to high rotational speeds.

In addition, when used as tuning parts already during the early development phase, isolators and dampers help improve the structural behavior of vehicle components and generate weight savings.