Commercial Vehicle Products | Motor Mounts

Transmission Mounts

Limit maximum deflections and provide vibration isolation from low to high frequencies

Limit maximum deflections and provide vibration isolation from low to high frequencies

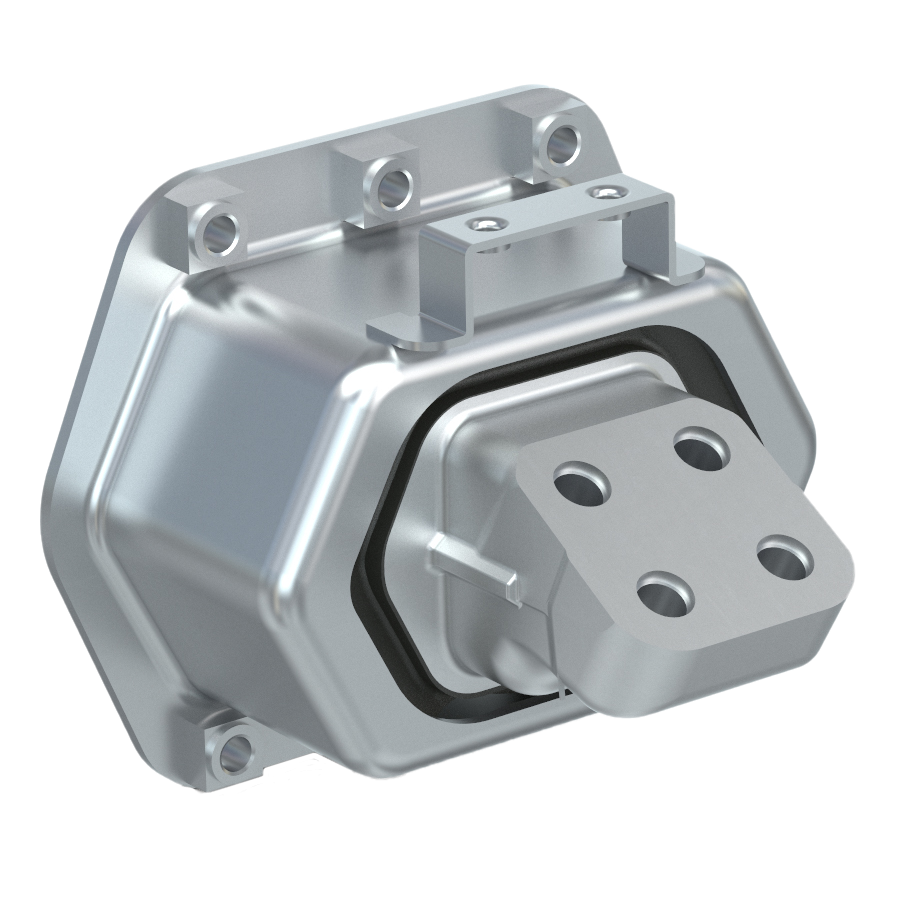

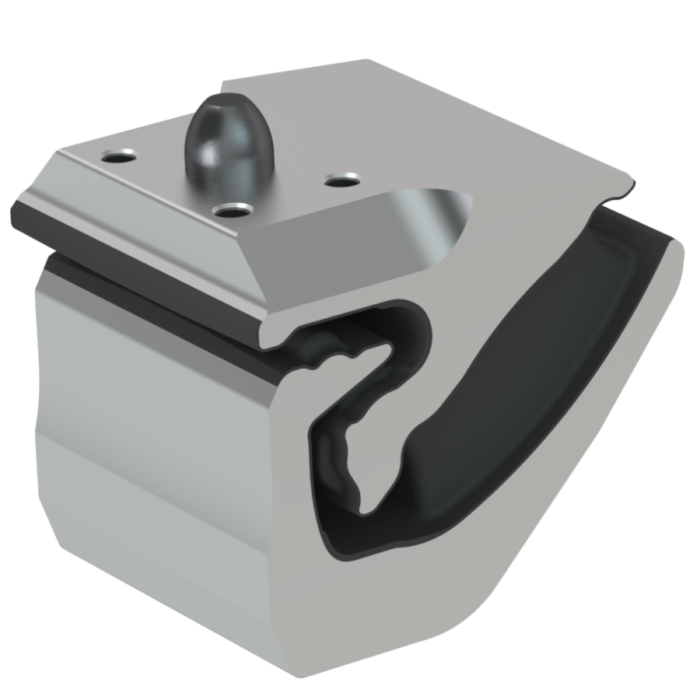

Transmission mounts are typically installed at the connection of the motor and the transmission. Exposed to the high static load of the drive train, they need to provide high durability. This is achieved by using aluminum for the metal components and a temperature-optimized rubber compound.

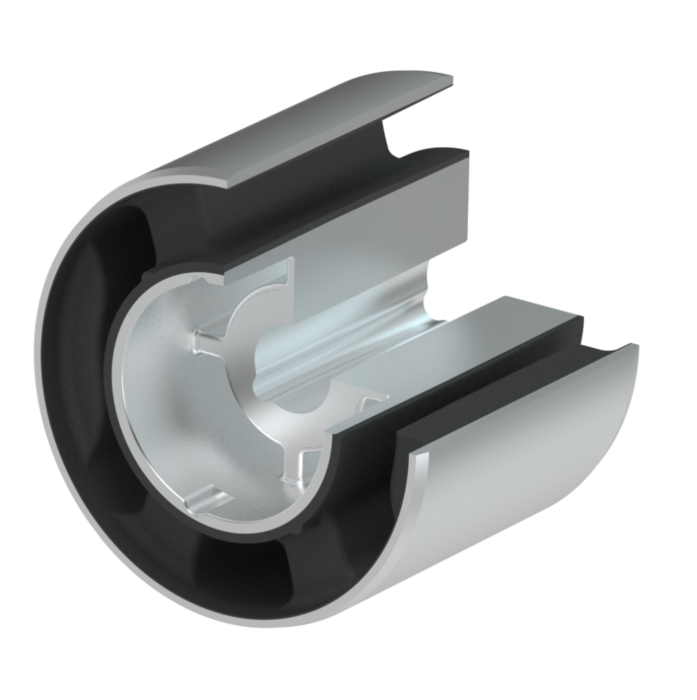

The rubber compound between the metal components is pre-stressed to the weight of the engine and transmission. The result is that the static load is already carried, and the movement of the rubber component is limited, resulting in high durability.

The specially developed natural rubber compound provides optimal NVH performance. It offers a progressive stiffness, which limits the maximum deflections of the engine while shifting, breaking and accelerating. Furthermore, the low basic stiffness for vibration isolation increases comfort and stability.

Using die-casted aluminum and a special design, the transmission mounts are weight and cost efficient and offer reliable performance in optimized packaging. Providing screw connections for the cables and insulation of the truck as well as bolting points secure the easy assembly.

About Motor Mounts

Motor mounts effectively isolate motor vibrations, dampen road excitations and support stability. Commercial vehicle drive trains with their heavy weight and high torques are a major source of vibrations. Commercial vehicle motor mounts from Vibracoustic help reduce noise and vibration, withstand high loads and torques, ensure reliable operation and are weight-optimized.

more

The transport industry is constantly striving for higher efficiency. Higher emission standards, demands for greater performance and high expectations for comfort further impact the requirements for motor mounts.

Exhaust gas treatment systems, turbochargers, higher pressure, encapsulation and additional equipment in and around the motor compartment boost service temperatures. Commercial vehicle motor mounts need to withstand those higher temperatures and at the same time isolate motor, drive train and road induced vibrations. Vibracoustic commercial vehicle motor mounts optimize NVH performance and improve the stability of the vehicle by reducing vibrations and motor movement.

Vibracoustic motor mounts work like a spring to dampen motor and road vibrations as well as road impacts. They are weight and cost-optimized as well as durable, reliable solutions that offer excellent NVH performance. The product portfolio includes front motor mounts, transmission mounts as well as motor mounts for electric trucks.