Light Vehicle Products

Motor Mounts

Motor mounts carry the static and dynamic loads of the motor throughout its entire service life and are also an important factor for isolating low to high frequency vibrations. Downsized and turbocharged motors are state-of-the-art to reduce fuel consumption but lead to high vibration levels.

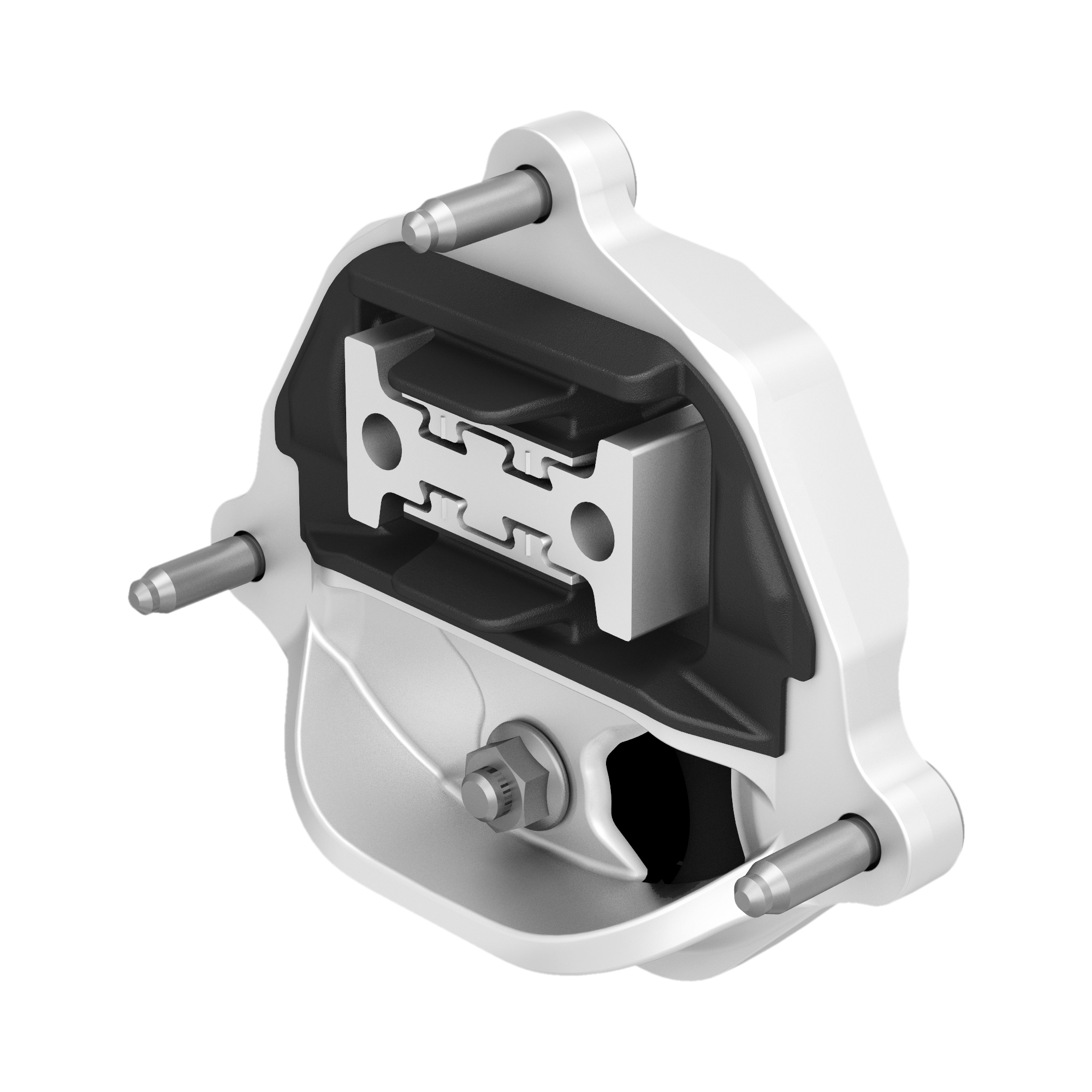

moreMotor and transmission mounts consist of a motor or gearbox support arm, an isolation element and a body-side connecting element. The critical element is the rubber spring that dampens vibrations, supports drive torques and isolates noise during start-up. The motor mount prevents booming noises and load-change shocks. Vibrations of the body and drive train are improved by using a hydraulic damping system. Motor mounts effectively isolate motor vibrations and dampen road excitations to ensure a comfortable driving experience.

The product portfolio ranges from conventional rubber mounts and hydro motor mounts, through electrically or pneumatically switchable motor mounts, to gearbox mounts and torque rods.

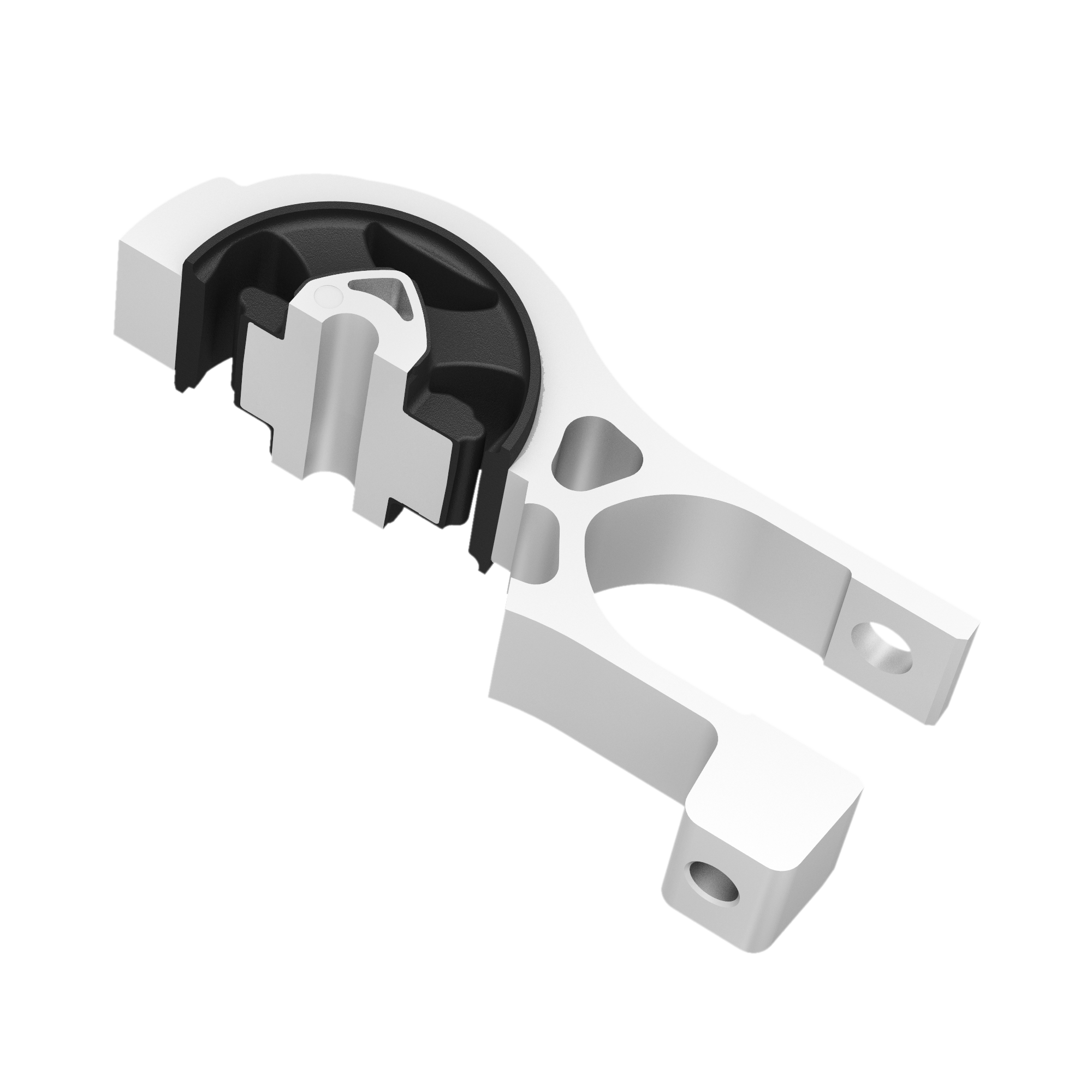

Quiettype Motor Mounts

Reduce the noise of electric motors across a broad and configurable frequency range

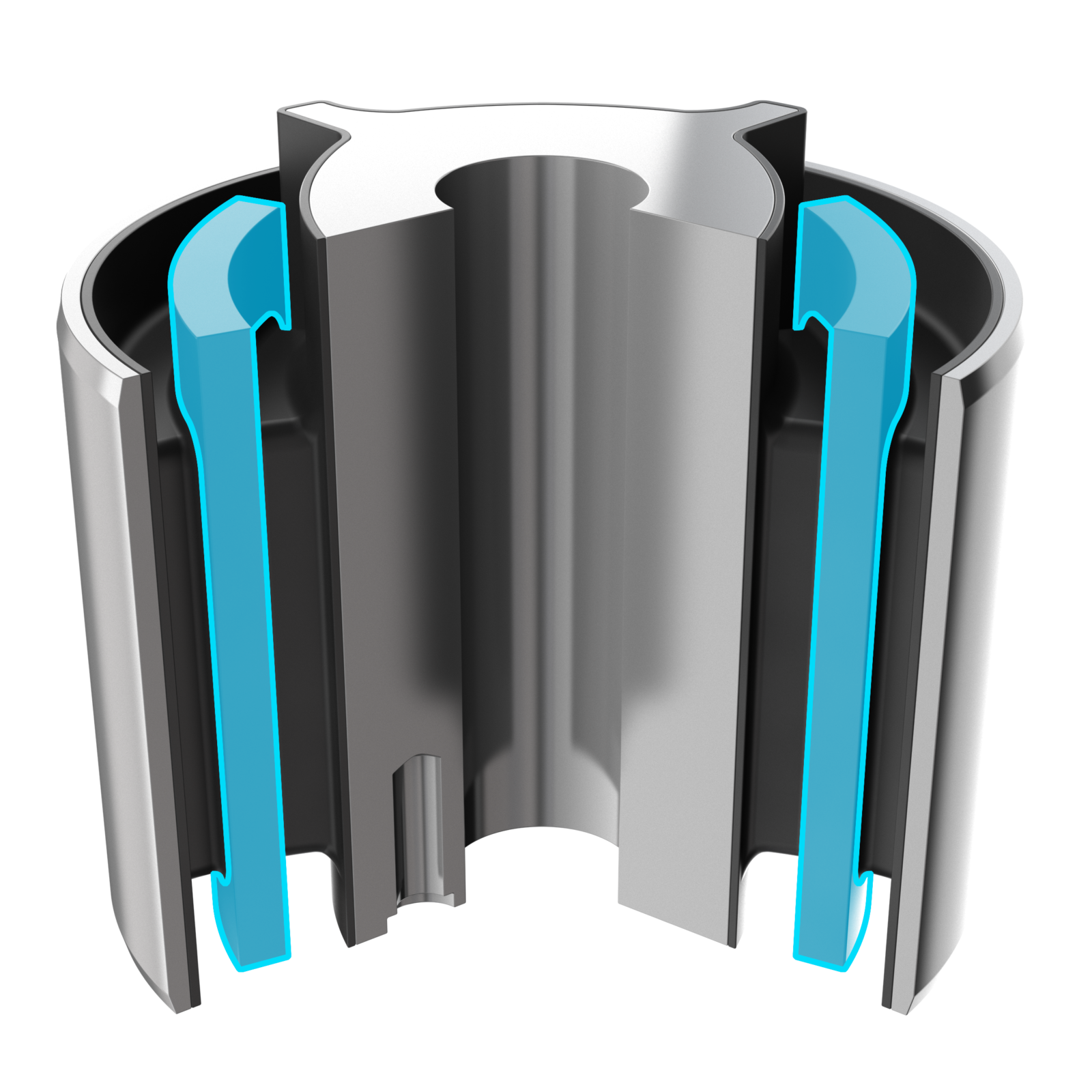

Switchable Hydro Motor Mounts

Isolate excitations at low amplitudes while dampening those at high amplitudes