Light Vehicle Products

Torsional Vibration Dampers

Torsional Vibration Dampers absorb rotational vibrations in internal combustion engines. The dampers are particularly effective in conjunction with decoupled pulleys, which keep crankshaft irregularities away from the belt drive and auxiliaries. In fuel-efficient start-stop systems, they eliminate the effects of an engine that is constantly starting and stopping. With an additional one-way-clutch feature, they can enable further savings in fuel consumption and CO2 emissions.

moreLight vehicle manufacturers are being increasingly challenged to downsize components to reach ambitious global targets for fuel consumption and CO2 emissions. The result is smaller engines with fewer cylinders that compensate for reduced capacity by building up increased pressure and enabling more efficient combustion. This generates stronger vibrations in the crankshaft. Torsional vibration dampers compensate rotational vibrations in the engine and the irregularities of the crankshaft are kept away from the belt drive, also ensuring optimized durability.

Torsional Vibration Dampers are offered in a wide range of processes and in a variety of materials – from pressed, high torque, vulcanized and fluid torsional vibration dampers, through damper isolator pulleys with an overrunning feature, to sprocket dampers.

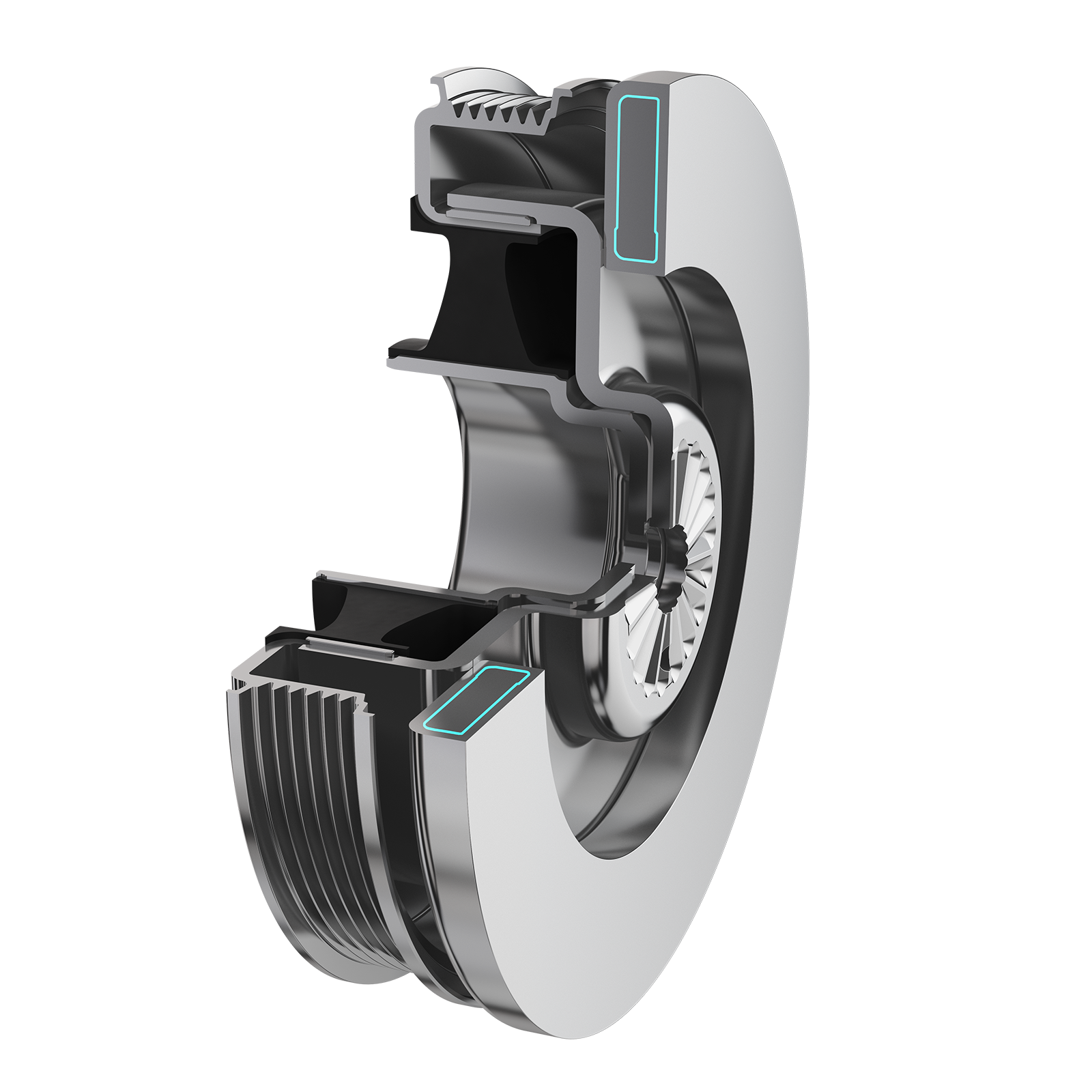

Damper Isolator Pulleys

Combine torsional vibration damping and an isolating function for the belt drive system

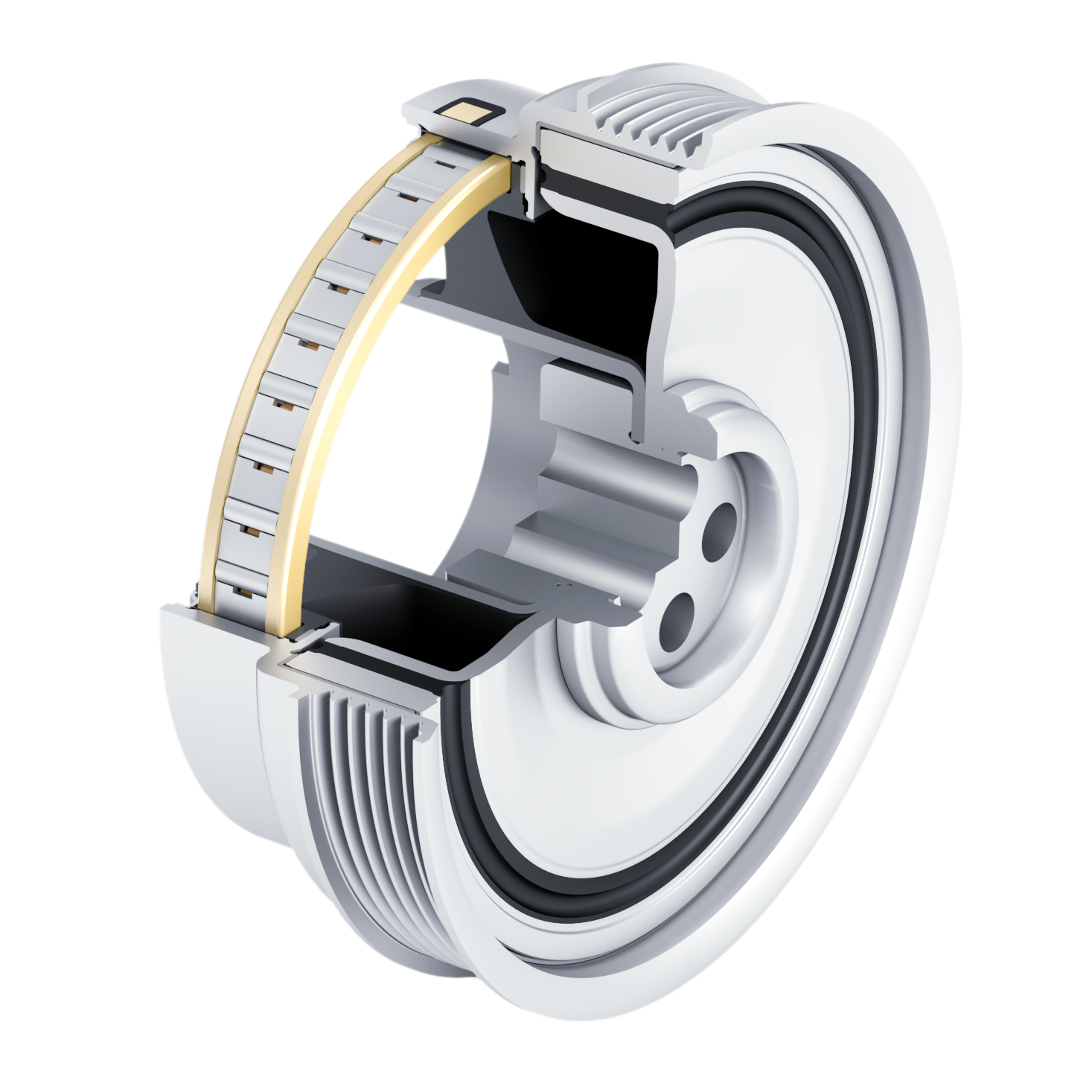

Fluid Torsional Vibration Dampers

Designed for when loads, damping and thermal load capacity are high

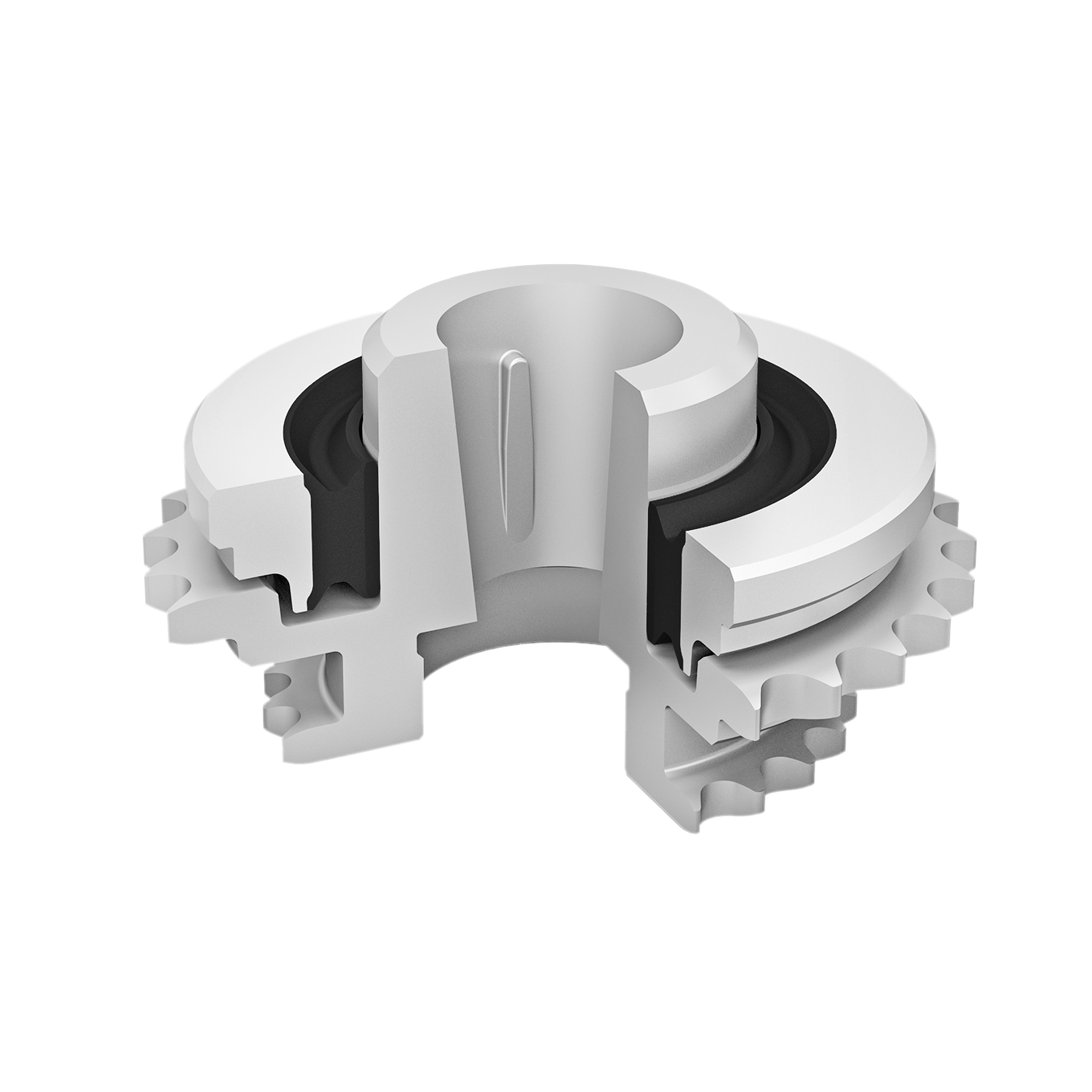

Pressed Torsional Vibration Dampers

Enable lightweight crankshaft design and cost-efficient noise radiation reduction

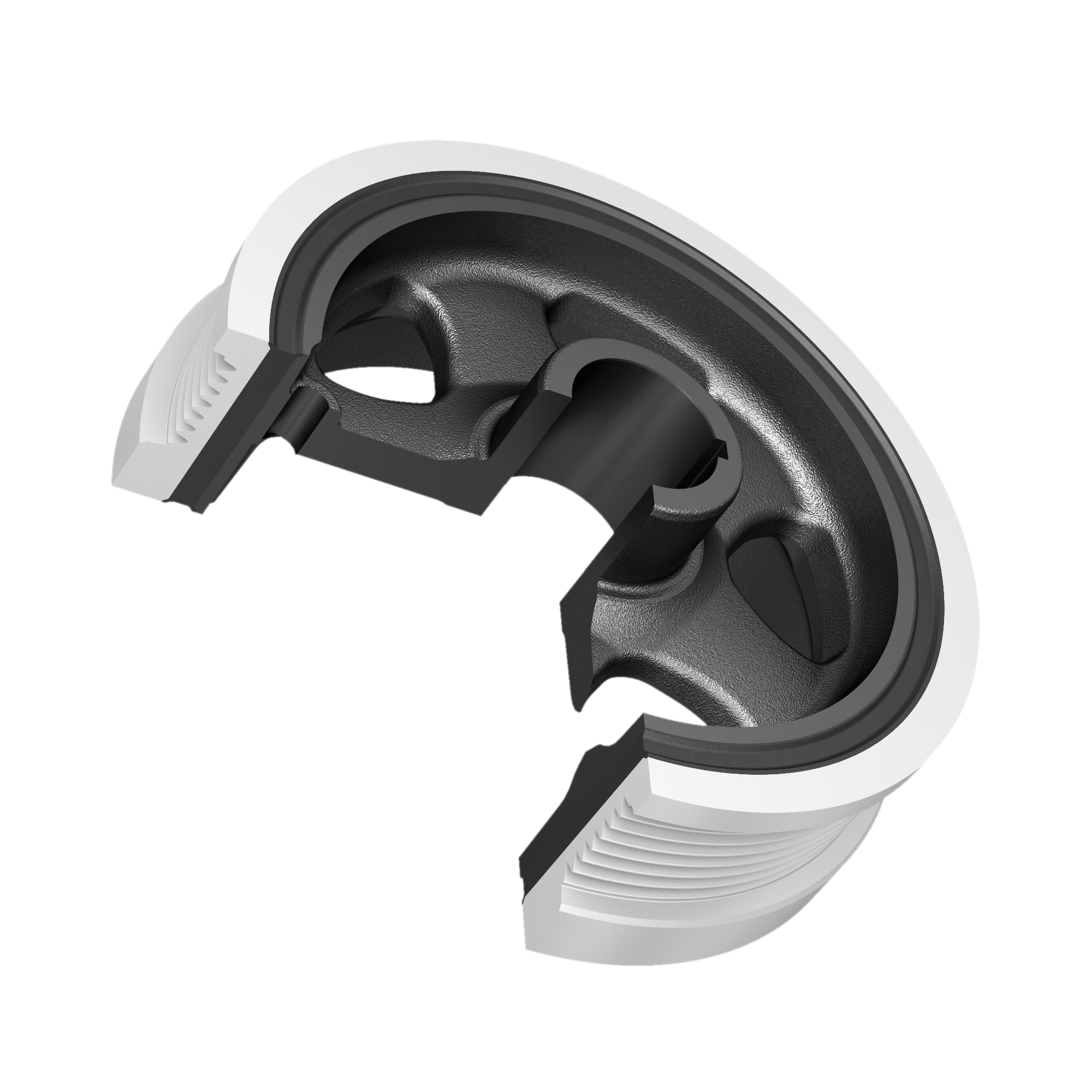

Vulcanized Torsional Vibration Dampers

Designed for high loads and high damping, increased motor life, and reduced noise and vibrations