Vibration Control Solutions from a Trusted, Reliable Partner

Light Vehicle Products

Vibracoustic’s power train solutions play a decisive role in reducing motor induced vibrations, regardless of the drivetrain concept. The portfolio offers engine, motor and transmission mounts, drive shaft dampers, exhaust mounts, center bearing supports, torsional vibration dampers and pulleys for a smooth, quiet and safe ride experience.

Vibracoustic’s chassis solutions, meanwhile, have a vital impact on handling, dynamics and comfort. The chassis has to transfer power to the road in an instant, support and cushion the vehicle, keep it on track, and bring it to a safe stop. The portfolio offers air springs, chassis, subframe and top mounts, bushings, microcellular urethane components, as well as isolators and dampers.

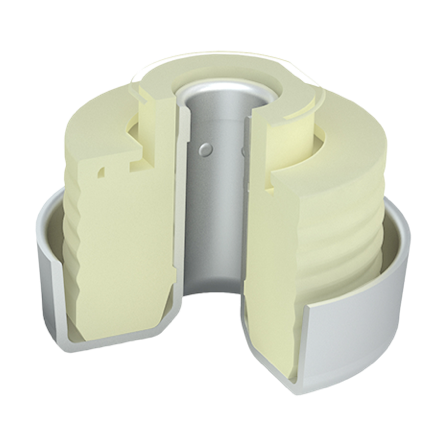

Air Springs

more

Vibracoustic supplies air springs for the majority of all light vehicles based on air suspension systems, making us one of the leading global air spring manufacturers.

Our products and technologies can be delivered separately or as a unit with the damper. The Vibracoustic portfolio ranges from front and rear axle air springs, to switchable multi-chamber air springs Our comprehensive air springs know how makes us a reliable and trusted component and module supplier for air spring applications of all sorts.

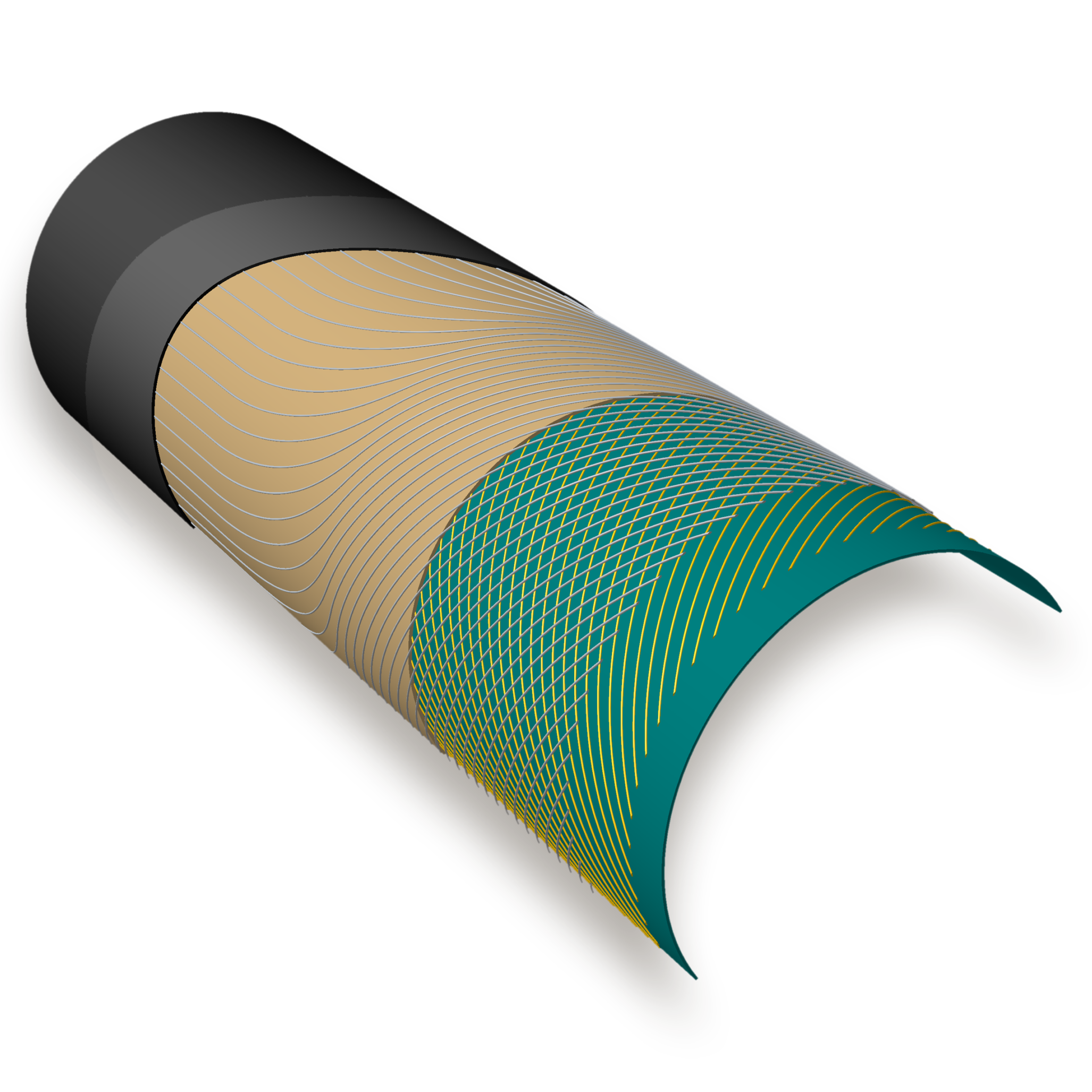

The key element in air springs for light vehicles are the rubber bellows. These essentially determine the comfort and service life properties. Vibracoustic offers three different types of bellows – axial, cross-ply and ZAX – which differ in terms of the structure of their embedded reinforcing fibers.

In an axial sleeve, the fibers embedded in the elastomer run axially to the deflection direction. The cross-ply bellows has two layers of reinforcing elements, placed at an angle to each other. Unlike in a fabric, these elements are not connected. The cross-axial bellows, or ZAX bellows, combines the great torsion decoupling capability of an axial sleeve with the dimensional stability of a cross-ply bellows.

Switchable Three-Chamber Air Springs

Resolve the conflicting objectives of comfort and good driving dynamics

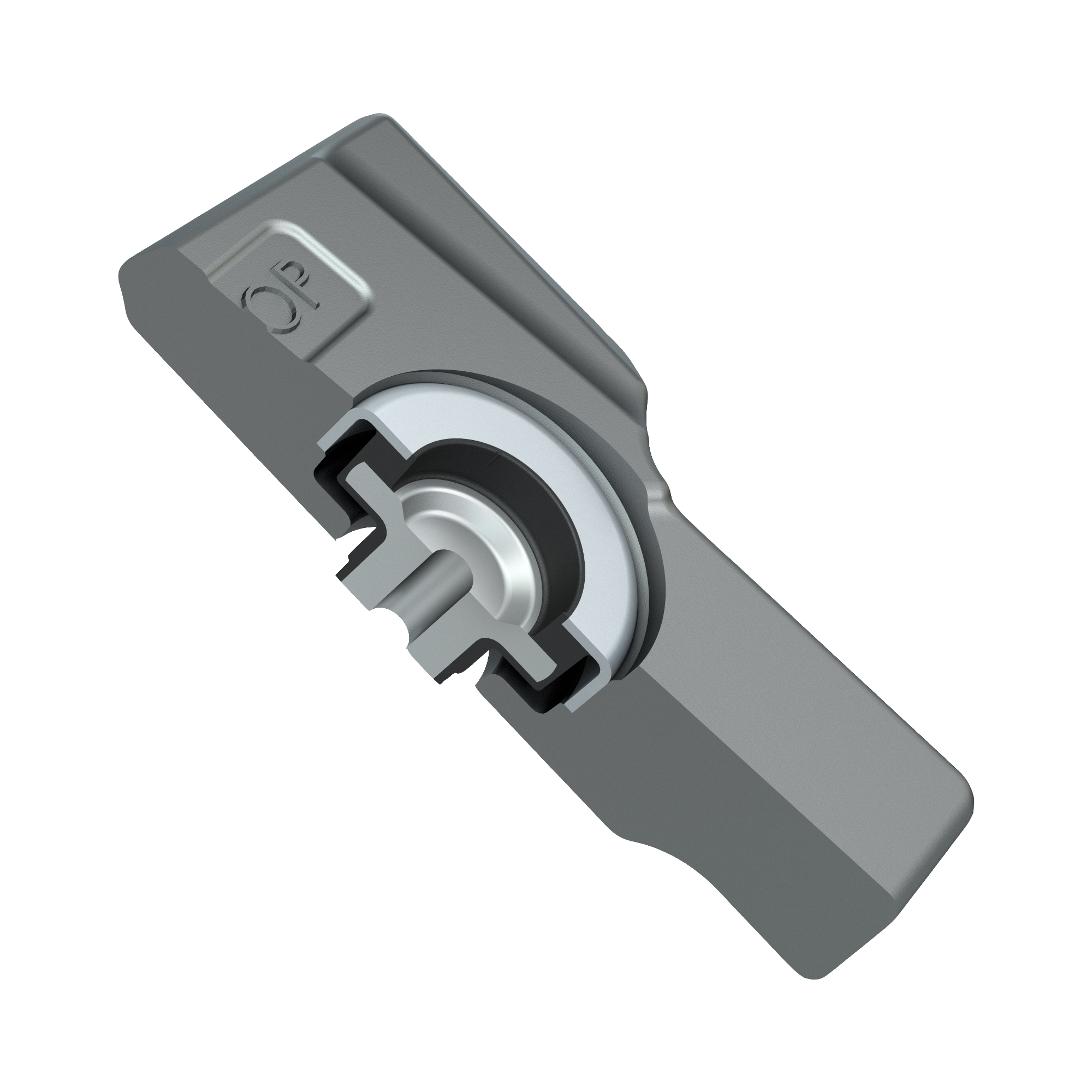

Centering Devices, Isolators & Dampers | Power Train

more

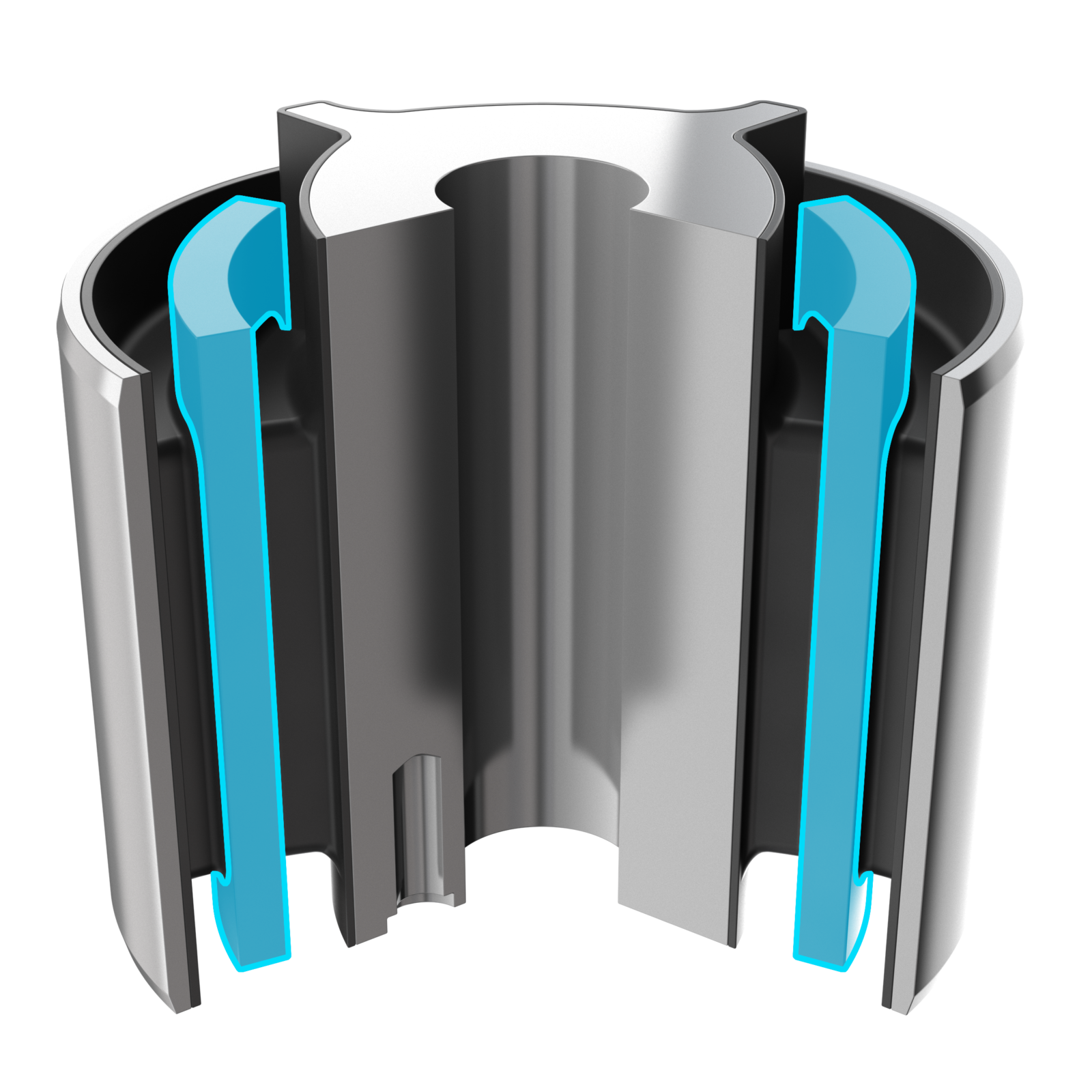

Our product portfolio includes flexible power train couplings and damping devices like the NRG-Disc (New Rubber Generation Disc), Tube-in-Tube or Drive Shaft Dampers. They smoothly transfer drive forces to the rear axle and reduce vibrations deriving from the torque fluctuations and natural frequencies of the drive shaft.

In addition to elastic decoupling elements, rotation dampers can be used to effectively reduce system-related resonance effects of the drive shaft.

Center Sleeves, Spherical Center Sleeves and Center Bearing Supports help align the drive shaft and allow flexible movements of the drive shaft while being constantly exposed to high rotational speeds.

In addition, when used as tuning parts already during the early development phase, isolators and dampers help improve the structural behavior of vehicle components and generate weight savings.

Drive Shaft Dampers

Reduce or eliminate torsional vibrations and natural frequencies at the drive shaft

NRG-Disc Flexible Rubber Couplings

Reduce effects of unwanted torsional vibrations and high frequency noises, offer a strong, compact and cost-effective drive shaft coupling

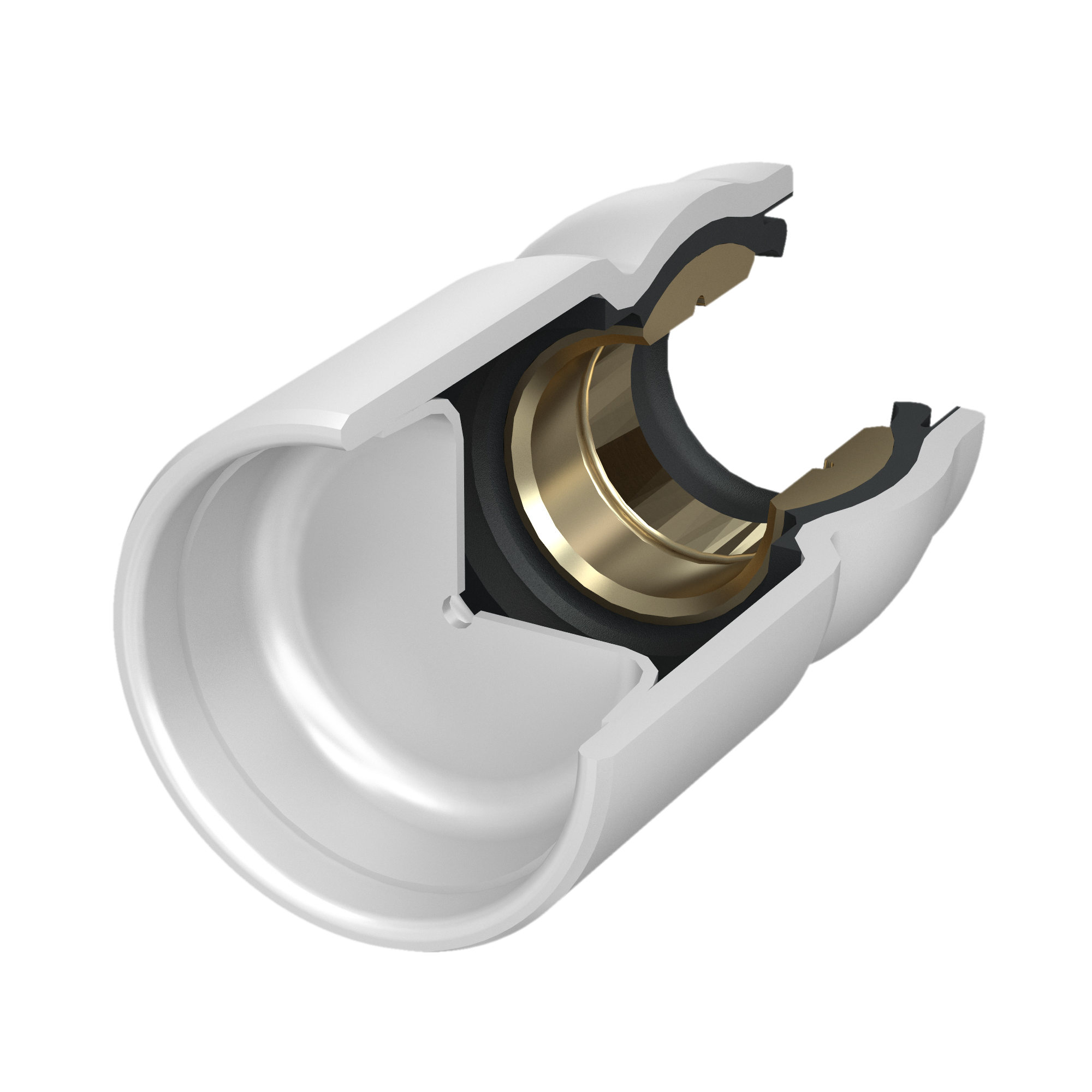

Spherical Center Sleeves

Align the gear box to the drive shaft and allow high cardanic angles using a spherical elastomer track

Chassis Mounts

more

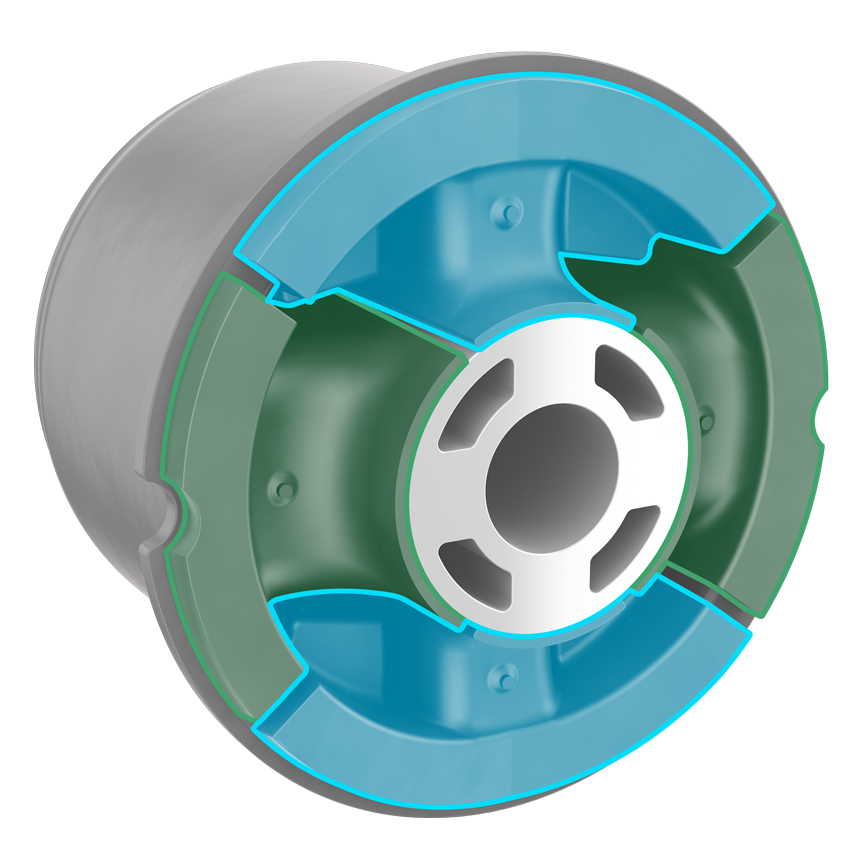

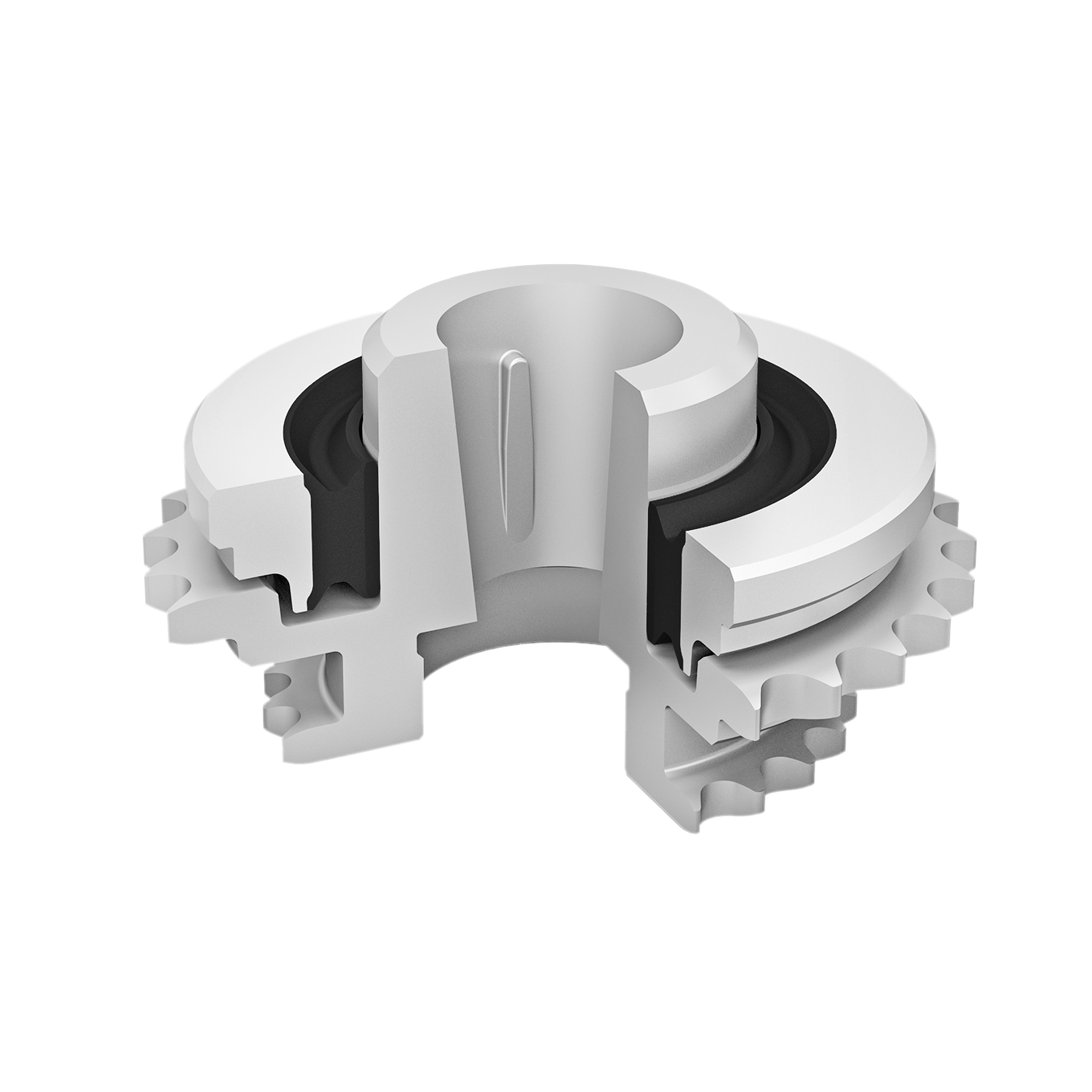

All bushings are designed to absorb loads, caused by road surface excitations, from multiple directions. The correct stiffness and damping of the bushings are essential to maximize vehicle road holding, ride and handling. Bushings must therefore be precisely tuned in line with the whole suspension system.

Minor vibrations create an unpleasant driving experience – severe ones can result in steering disturbances and body vibrations that pose serious safety risks. To reduce vibrations, vehicles have a number of chassis mounts fitted, e.g. for the transverse control arms, subframes, suspension struts and stabilizers.

The product portfolio ranges from conventional, hydro, DualRubber chassis bushings through steering column bushings, and subframe mounts to conventional and lightweight top mounts.

Isolators & Dampers | Chassis

more

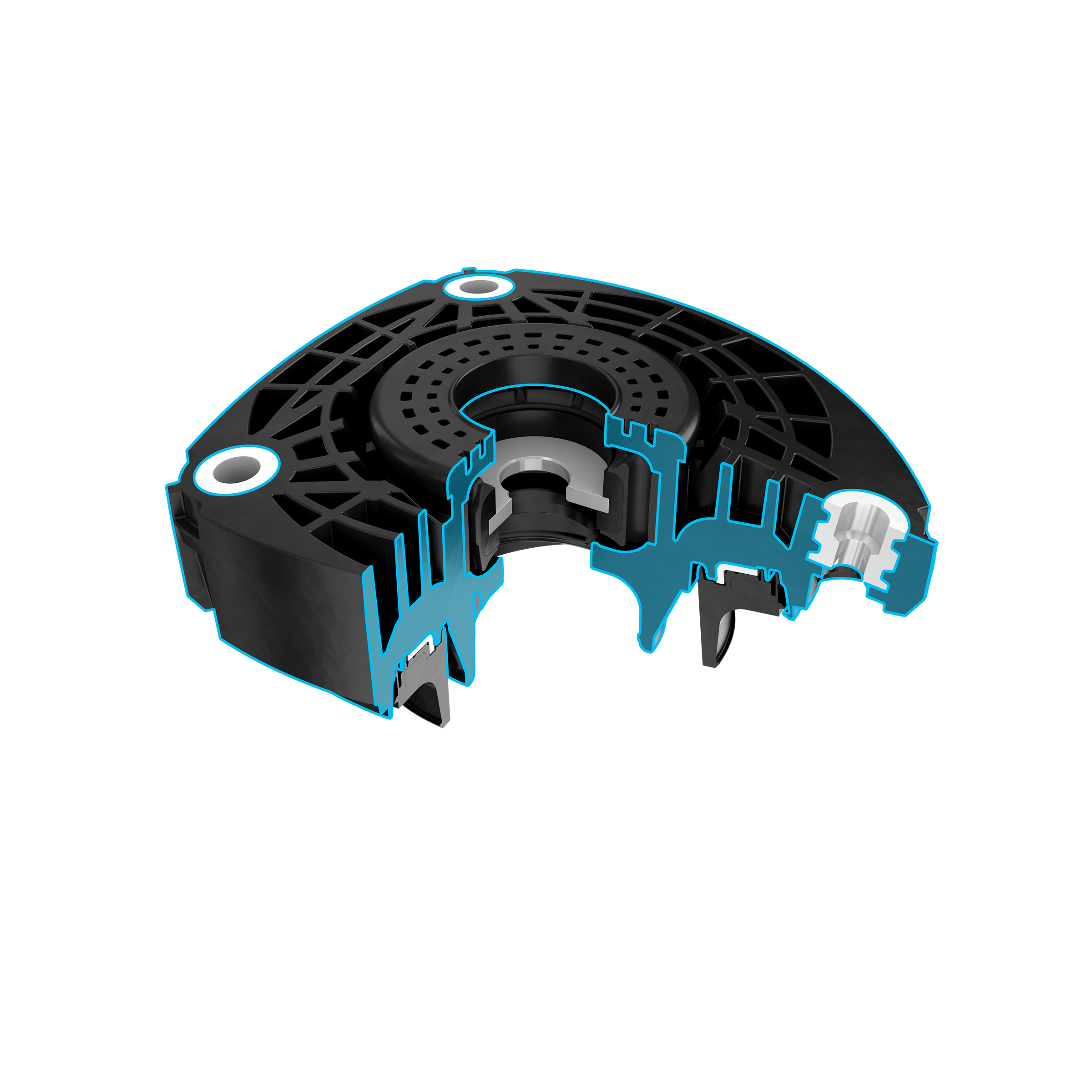

Mass dampers are ideal for use in applications where vibrations need to be balanced with opposing inertial forces. In these configurations, an additional spring-mass system with the same frequency, but opposite amplitude, acts on the vibrating structure, effectively eliminating its vibrations. The way mass dampers work means they can be used in a wide variety of scenarios: transmissions, steering wheels, and even whole convertibles are just some of the applications that make use of this indispensable system to prevent Noise, Vibration and Harshness issues.

Active mass dampers are another way of improving comfort even further. They use a sensor placed on the vibrating structure and an ECU (Electric Control Unit) that controls a solenoid which is able to accelerate the absorber mass. This way, active mass dampers not only come with a design that weighs less and takes up less space than their conventional counterparts, but they are also able to adjust to variables such as additional cargo load, road surface excitation, and temperature.

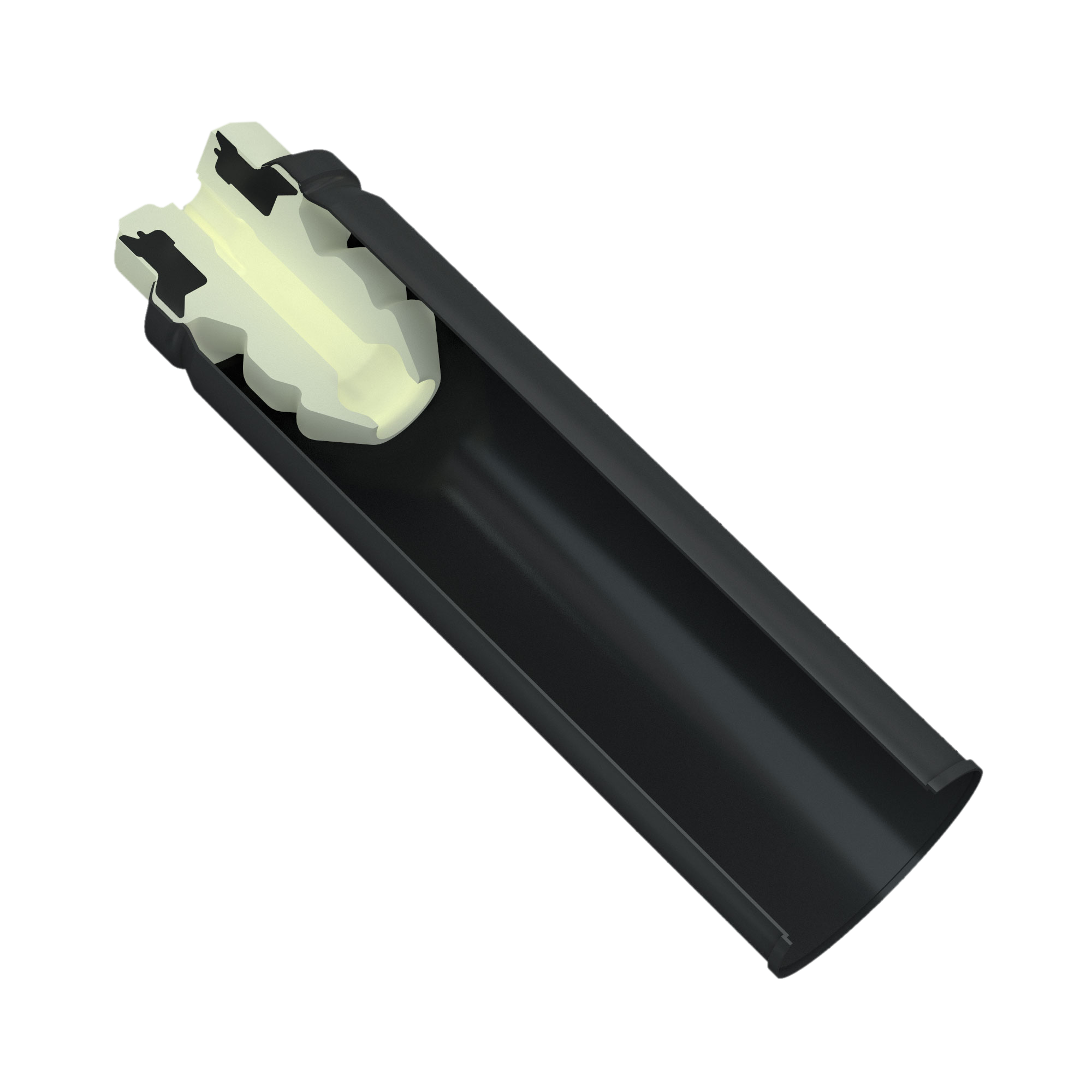

MCU Components

more

The automotive industry needs to meet the increasing demand for lighter vehicles while integrating new components, like hybrid drives. As a result, the space available for a vehicle’s spring and isolation elements becomes smaller. Vibracoustic’s engineers work closely with vehicle manufacturers to supply a full range of materials that combine maximum performance within the ever decreasing available space.

MCU helps fulfill these requirements. Similar to a sponge, MCU absorbs energy and isolates noise, yet is strong enough to bear the weight of an entire vehicle. MCU components also offer a low weight, progressive stiffness with excellent long-term behavior when subjected to cold, heat, and the environment.

Vibracoustic offers multiple material and design options, including assembly with dust covers and saturation cups or as part of complete components like top mounts and air springs.

MCU Body Mounts

Locate and isolate the vehicle's body from the frame, while improving the vehicle comfort and handling qualities

MCU Jounce Bumpers

Enable ride tuning, absorb energy from irregular road events, and support vehicle handling requirements

MCU Top Mounts

Isolate road noise and more effectively react shock loads with high amplitude damping and a long linear rate response

Motor Mounts

more

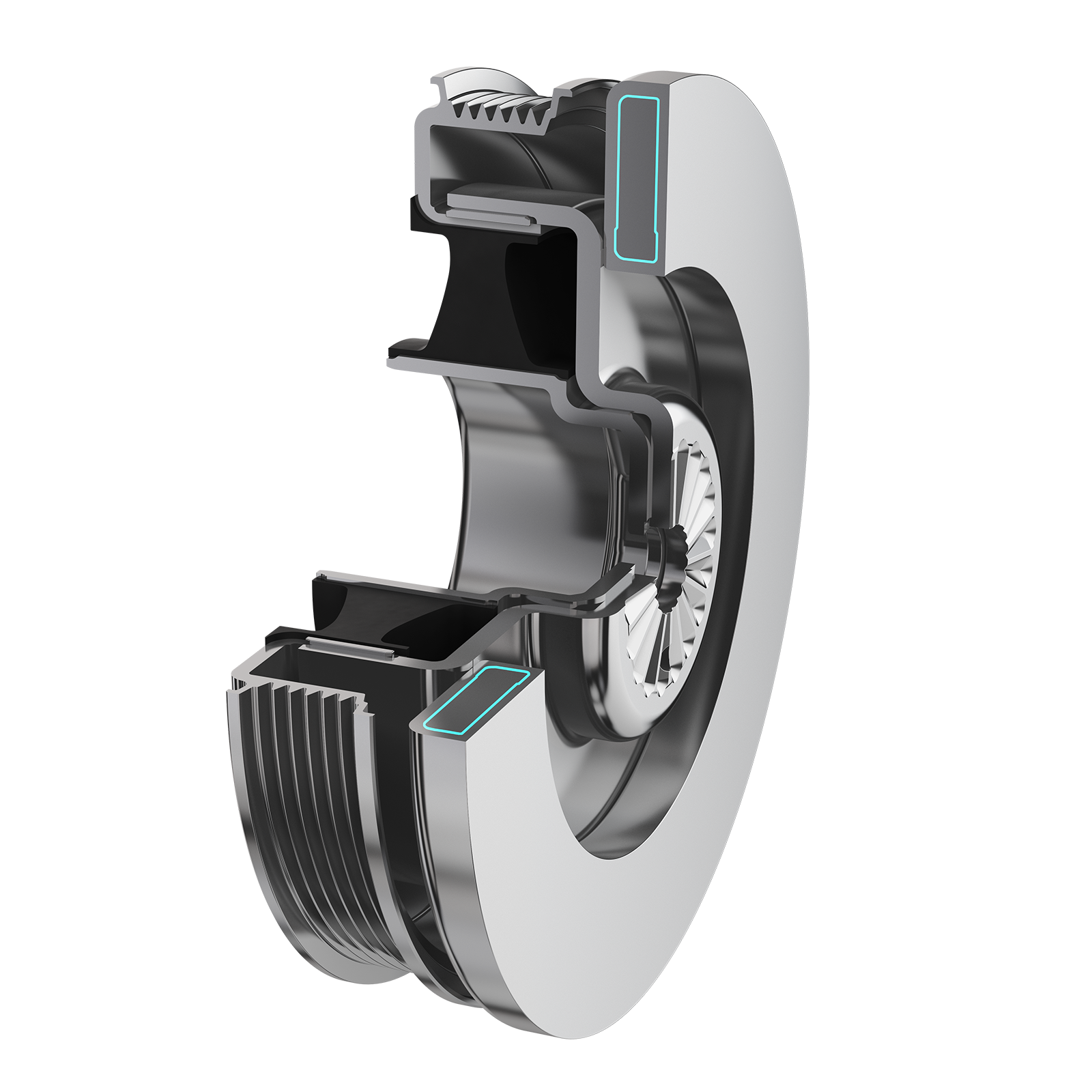

Motor and transmission mounts consist of a motor or gearbox support arm, an isolation element and a body-side connecting element. The critical element is the rubber spring that dampens vibrations, supports drive torques and isolates noise during start-up. The motor mount prevents booming noises and load-change shocks. Vibrations of the body and drive train are improved by using a hydraulic damping system. Motor mounts effectively isolate motor vibrations and dampen road excitations to ensure a comfortable driving experience.

The product portfolio ranges from conventional rubber mounts and hydro motor mounts, through electrically or pneumatically switchable motor mounts, to gearbox mounts and torque rods.

Quiettype Motor Mounts

Reduce the noise of electric motors across a broad and configurable frequency range

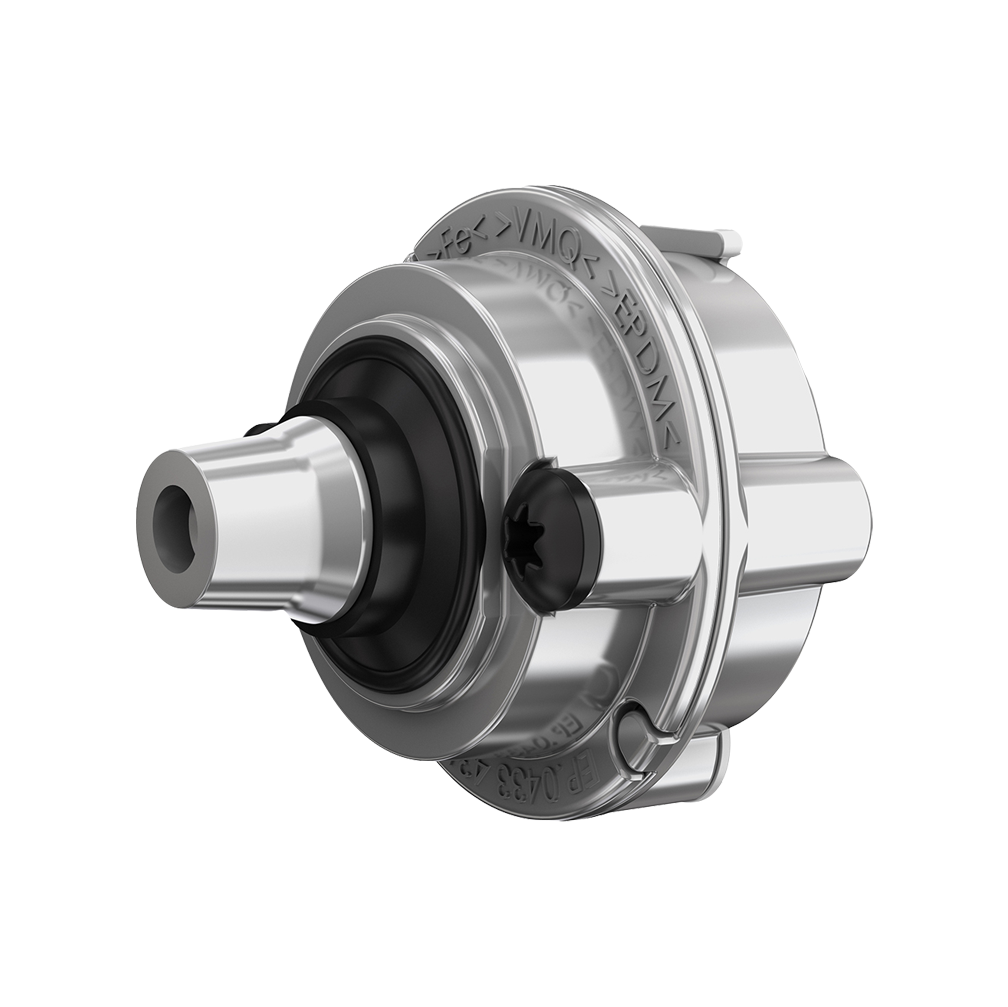

Torsional Vibration Dampers

more

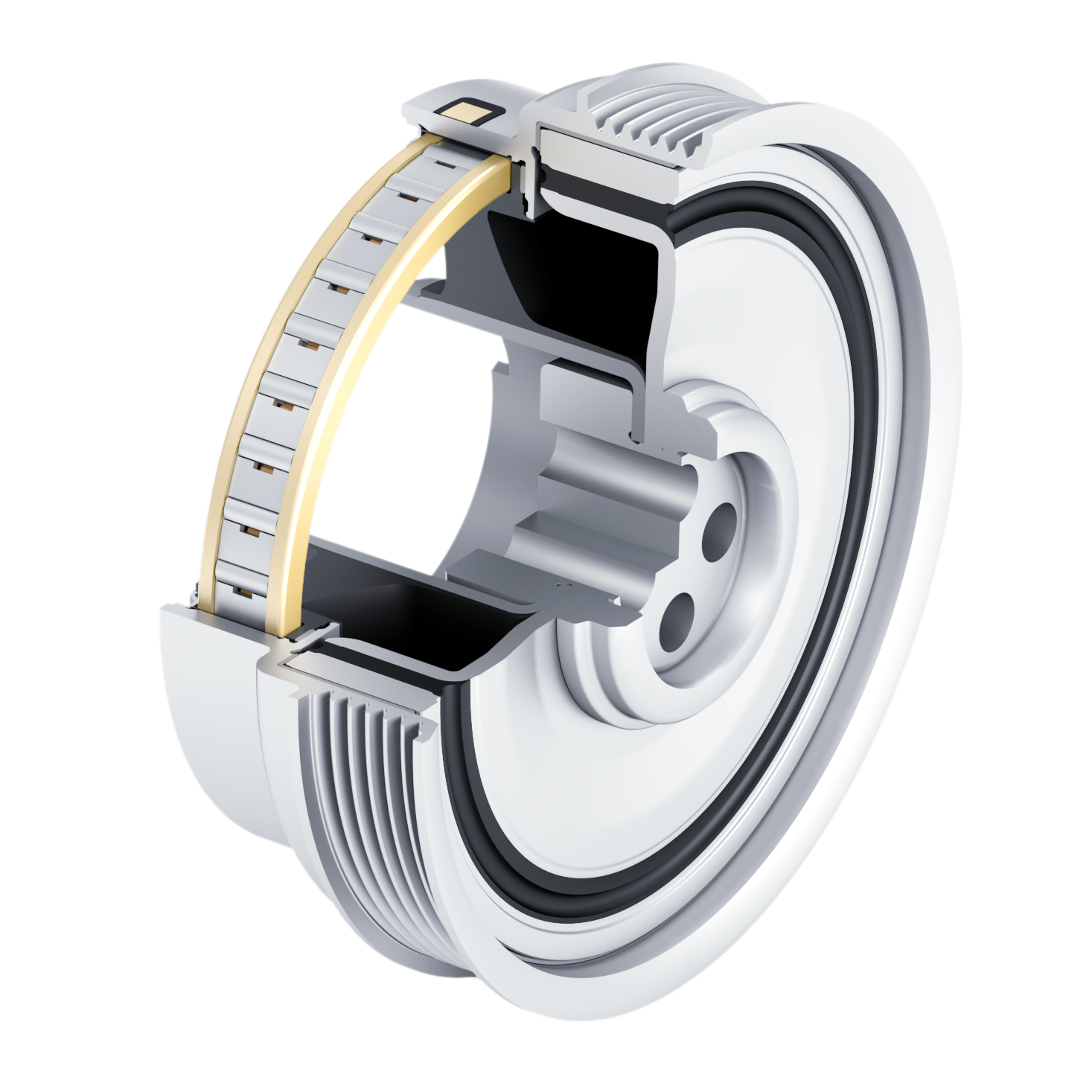

Light vehicle manufacturers are being increasingly challenged to downsize components to reach ambitious global targets for fuel consumption and CO2 emissions. The result is smaller engines with fewer cylinders that compensate for reduced capacity by building up increased pressure and enabling more efficient combustion. This generates stronger vibrations in the crankshaft. Torsional vibration dampers compensate rotational vibrations in the engine and the irregularities of the crankshaft are kept away from the belt drive, also ensuring optimized durability.

Torsional Vibration Dampers are offered in a wide range of processes and in a variety of materials – from pressed, high torque, vulcanized and fluid torsional vibration dampers, through damper isolator pulleys with an overrunning feature, to sprocket dampers.

Fluid Torsional Vibration Dampers

Designed for when loads, damping and thermal load capacity are high