Light Vehicle Products | Motor Mounts

Active Hydro Motor Mounts

Neutralize incoming vibrations and reduce noise by up to 20dB

Neutralize incoming vibrations and reduce noise by up to 20dB

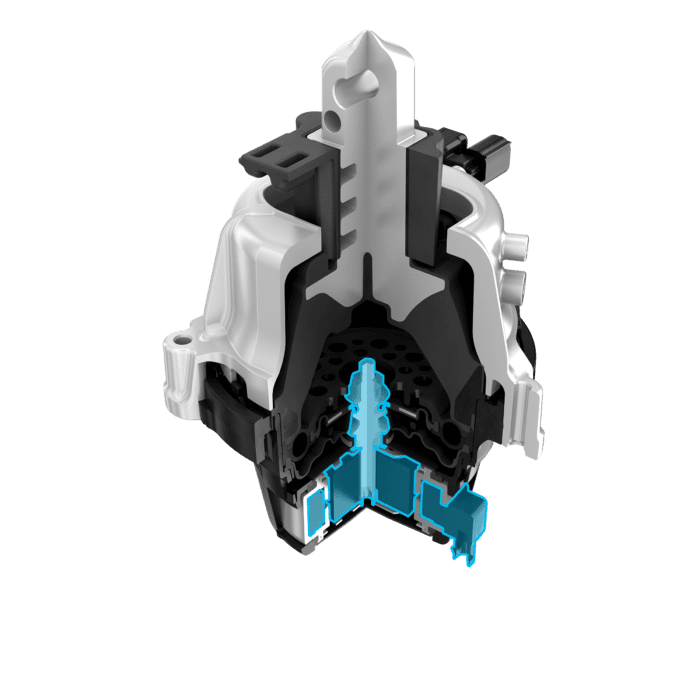

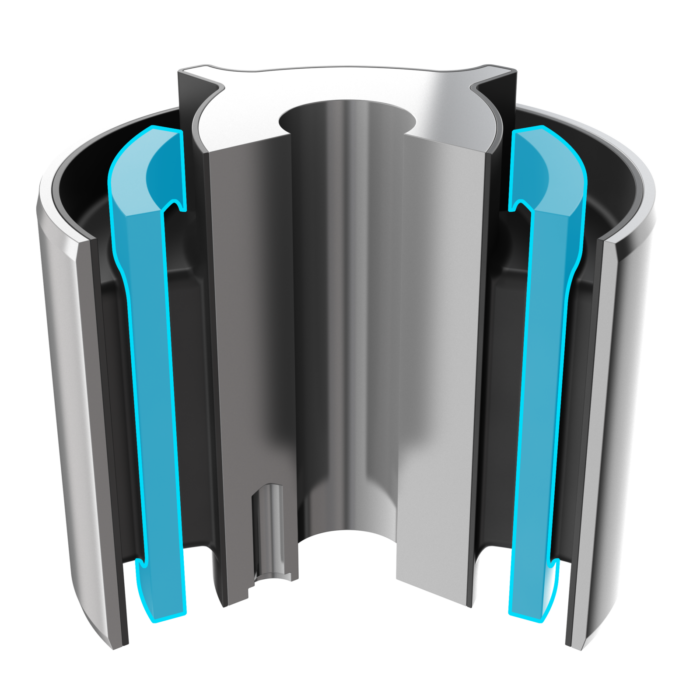

Active motor mount systems use specially generated compensation movements to neutralize the incoming engine vibrations. The basic principle lies in neutralizing incoming sine wave vibrations by applying electrically generated compensation movements. These compensation movements are set at the same frequency. The appropriate setting of the phase position prevents the vibrations being transferred into the chassis and felt inside the cabin, which ultimately increases the driving comfort for the passengers.

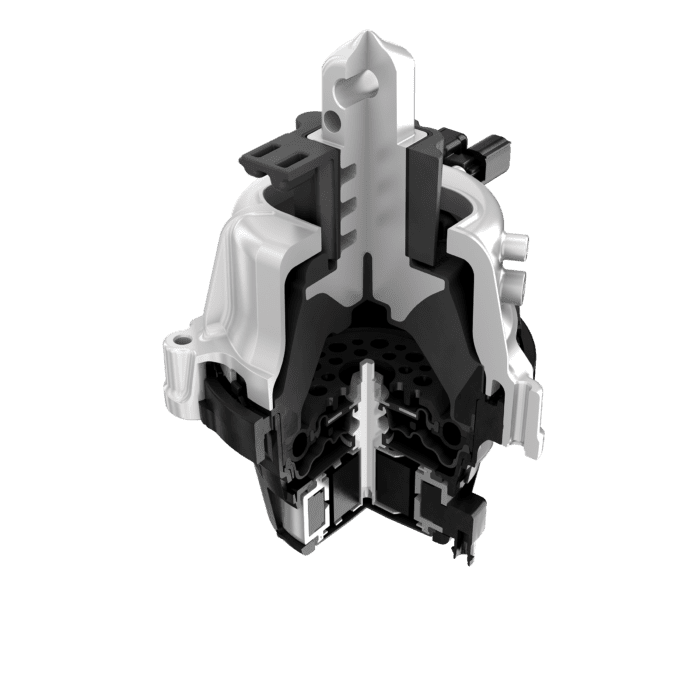

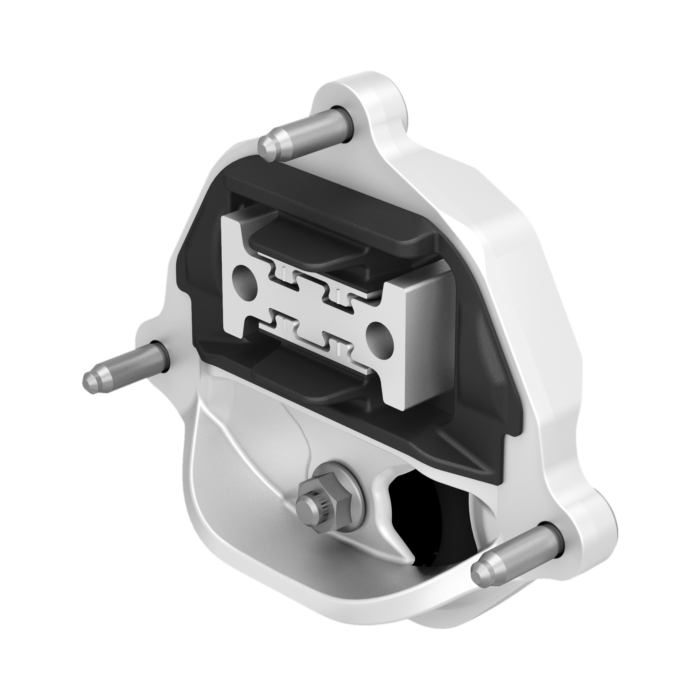

When low frequency, high amplitude road excitations occur, the active hydro mount functions as a conventional mount and an oscillation of the engine is damped by the movement of the liquid. When high frequency, low amplitude engine excitations occur, from idle to full load operations, the conventional hydro mount can no longer follow the quick movement due to the inertia of the fluid. Here the active function of the hydro mount comes into play. It can operate the actuator up and down to control the inside pressure of the fluid and therewith adjust the dynamic stiffness of the mount, enhancing the vibration isolation performance while driving.

The active hydraulic motor mounts can work in a frequency range of 20-200 Hz and the generated compensation movements can lead to a noise reduction of up to 20dB under partial load conditions and a reduction of up to 15dB under full load conditions, which is a clearly noticeable difference for the passengers.

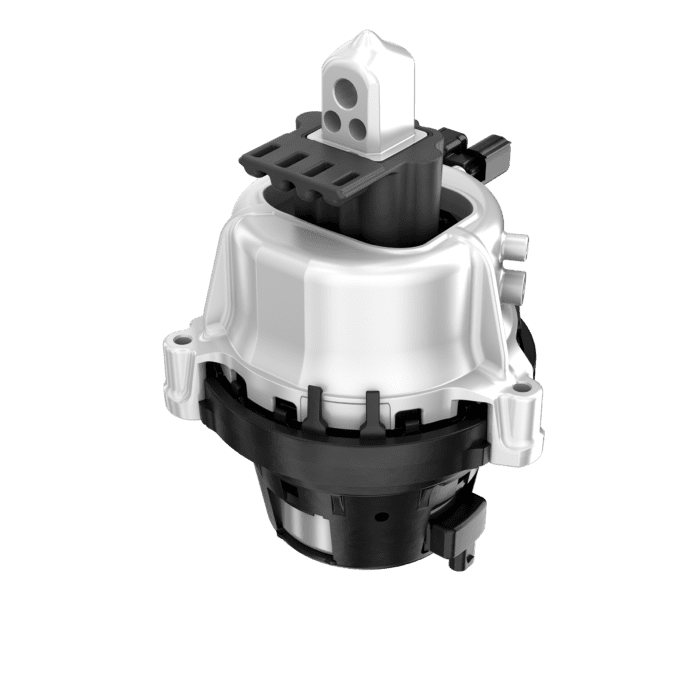

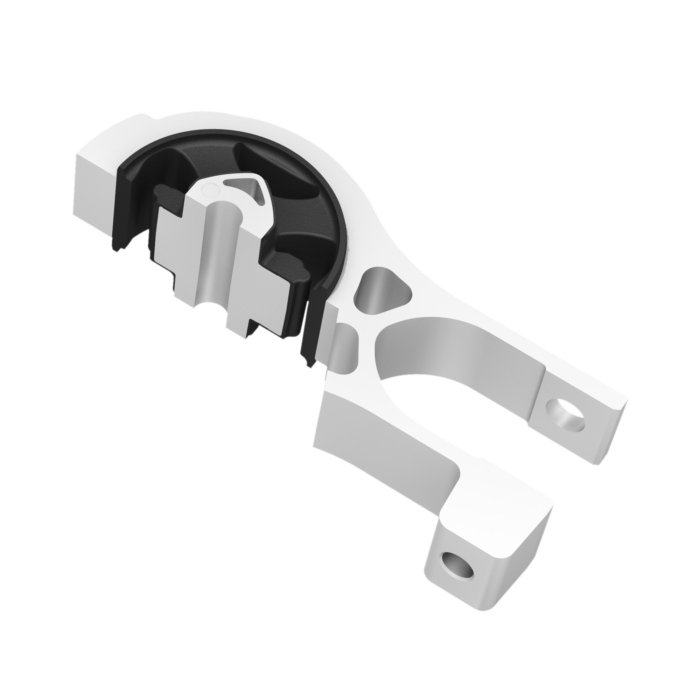

Active motor mount systems consist of a hydraulic motor mount with an actuator, an analog acceleration sensor and an electronic control unit (ECU). Whereas the acceleration sensor measures the excitations coming from the engine, the ECU calculates in real-time the needed compensation movements and sends them to the actuator within the active hydro mount to cancel out the incoming vibrations.

As a leading NVH expert for the automotive industry, Vibracoustic is able to develop active hydro mounts including dedicated simulation tools and verification with component, subsystem and vehicle tests. Vibracoustic is also able to realize the software integration of the ECU into the vehicle software environment. .

About Motor Mounts

Motor mounts carry the static and dynamic loads of the motor throughout its entire service life and are also an important factor for isolating low to high frequency vibrations. Downsized and turbocharged motors are state-of-the-art to reduce fuel consumption but lead to high vibration levels.

more

Motor and transmission mounts consist of a motor or gearbox support arm, an isolation element and a body-side connecting element. The critical element is the rubber spring that dampens vibrations, supports drive torques and isolates noise during start-up. The motor mount prevents booming noises and load-change shocks. Vibrations of the body and drive train are improved by using a hydraulic damping system. Motor mounts effectively isolate motor vibrations and dampen road excitations to ensure a comfortable driving experience.

The product portfolio ranges from conventional rubber mounts and hydro motor mounts, through electrically or pneumatically switchable motor mounts, to gearbox mounts and torque rods.