Commercial Vehicle Products | Air Springs

Lighttronics

Offer significant weight savings, high comfort and robustness for maximum efficiency

Offer significant weight savings, high comfort and robustness for maximum efficiency

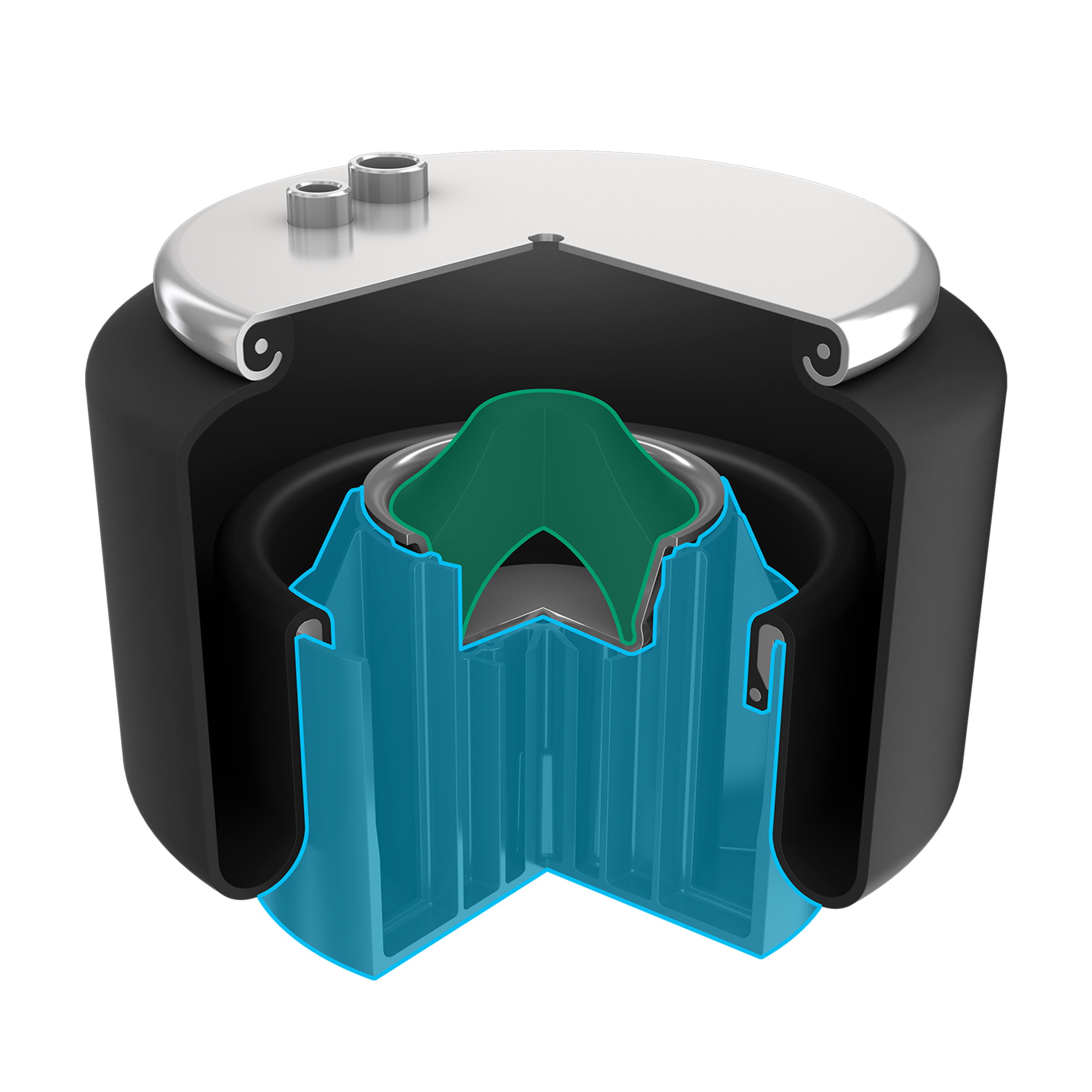

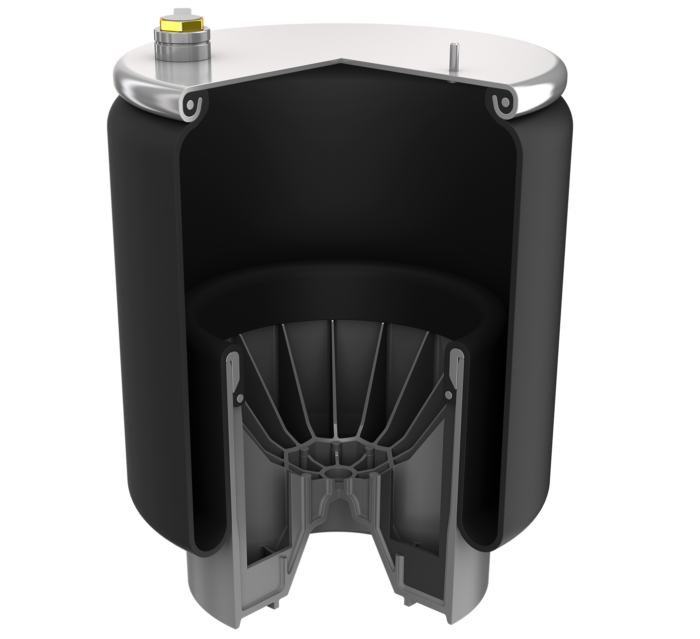

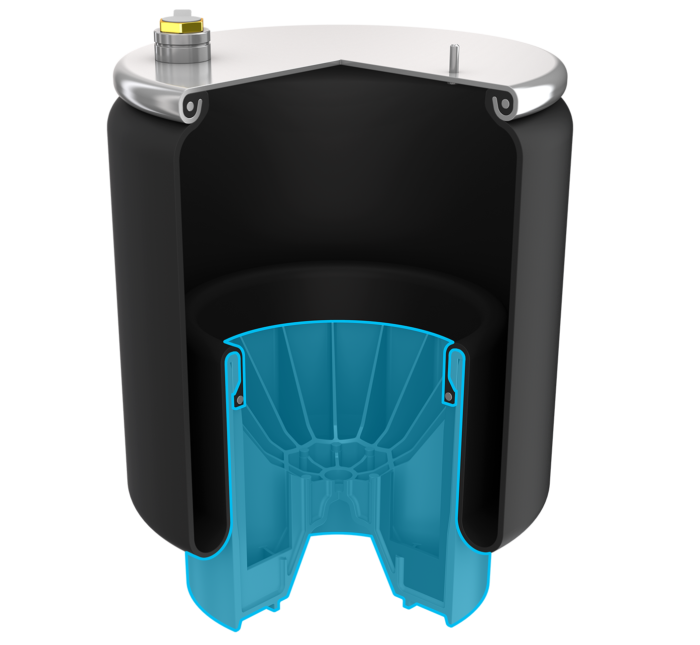

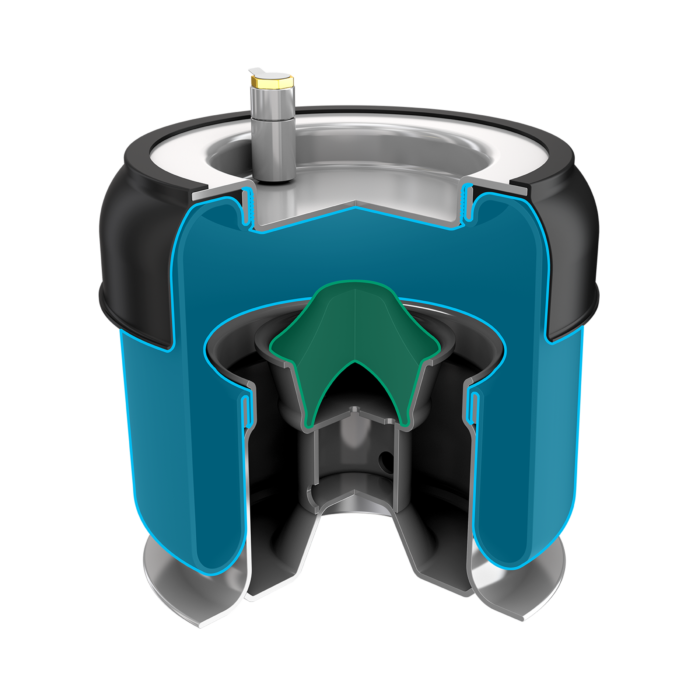

The development of the Lighttronics lightweight commercial vehicle air spring is an engineering masterpiece from Vibracoustic. With the goal to reduce the weight of air springs for trucks and busses, Vibracoustic engineers replaced the heavy steel piston with a lightweight plastic design. Unlike other plastic pistons, the Vibracoustic Lighttronics air springs have a plastic piston made out of one piece without any weld. Avoiding welds in plastic pistons is a big challenge, but it pays off as avoiding the welding seam removed a particularly weak point of those products. Achieving the maximum available air spring volume like comparable steel pistons as well as significantly reducing the unswung mass, the Vibracoustic one-piece plastic composite piston design offers maximum performance when it comes to comfort and vehicle stability and helps to reduce fuel consumption and CO2 emissions.

The seamless outer length of the plastic piston is longer compared to comparable lightweight air springs, allowing a longer spring travel and therefore a broader range of commercial vehicle applications. In addition, an innovative self-sealing connection between the maximum volume composite piston and the air bellow was developed. The result is an optimized air spring characteristic and a faster vehicle lifting with a high level of comfort and excellent vehicle stability under all driving conditions. Especially for busses and coaches, where passenger comfort is key, Lighttronics air springs are an excellent solution and are available with an integrated comfort bumper for even higher comfort.

A plastic piston is non-corrosive, needs less maintenance and offers high durability. The fiberglass-reinforced, heat and cold-resistant plastic piston from Vibracoustic has a very high energy absorption, resulting in reliable protection against damages like stone impacts. Lighttronics commercial vehicle air springs are robust and resistant to environmental influences.

About Air Springs

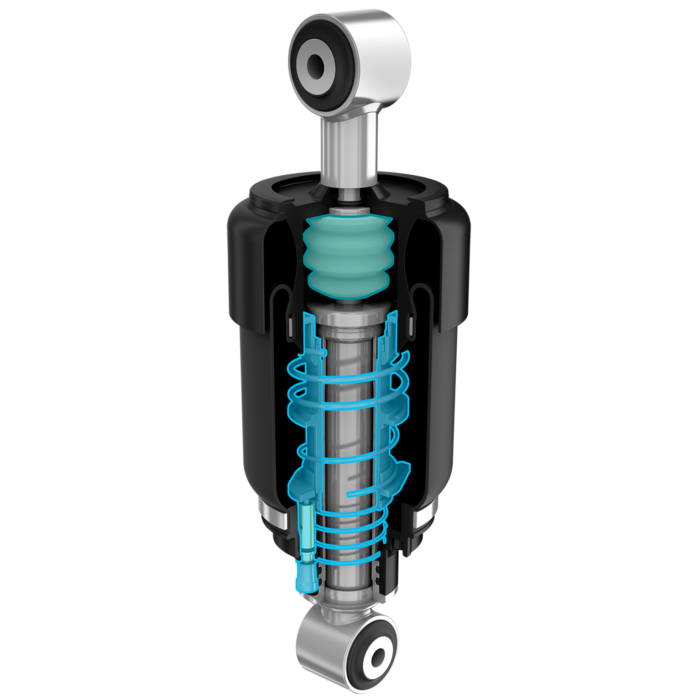

From the minimum loads of an unhitched tractor to the weight of a fully-loaded trailer, commercial vehicle axles need to cover extreme load fluctuations with the rear axles being exposed to the main load of those fluctuations. With their ability to quickly change the spring rate according to the current load situation, commercial vehicle air springs are an excellent solution for this challenge. Therefore, they are used in most commercial vehicles like trucks and buses as well as in trailers.

more

Commercial vehicle air springs from Vibracoustic CV Air Springs offer an excellent combination of reliability, safety, and comfort for trucks, tractors, trailers and buses. By adding or releasing air, the same level of driving comfort can be provided and a constant height can be maintained for all load situations.

Keeping the vehicle and trailer at a constant height level maintains vehicle stability and provides safe driving characteristics. Furthermore, it improves vibration damping in all load conditions. This reduces axle, transmission and tire wear and increases vehicle durability and efficiency. In addition, the truck suspension cannot bottom out thanks to the air springs and the chassis and the transported goods are strongly protected from damage.

The driver as well benefits from improved vibration damping, which provides high driving comfort and reduces driver fatigue for a relaxed and secure haulage.