Light Vehicle Products | MCU Components

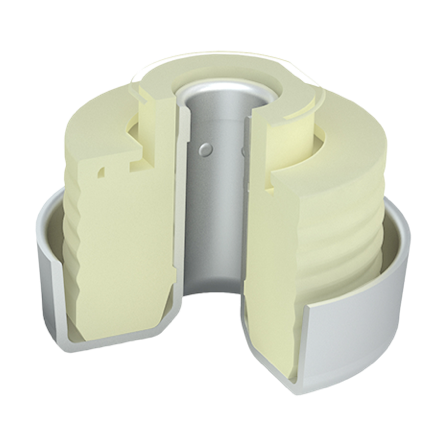

MCU Spring Isolators

Support vehicle weight, isolate rolling noise, and provide even loading of the spring

Support vehicle weight, isolate rolling noise, and provide even loading of the spring

In every strut suspension, two coil spring isolators are typically used. The so-called lower isolator is positioned between the coil spring and the spring seat on the strut, while the other is located between the coil spring and the top mount. They are used to provide rolling noise isolation and prevent metal-to-metal contact between the spring and the strut or top mount.

Spring isolators can be supplied assembled to complete components like top mounts, jounce bumpers, or air springs, as well as being equipped with dust covers, bumpers or saturation cups.

Vibracoustic offers multiple Micro Cellular Polyurethane (MCU), thermoplastic rubber, and thermoset rubber material options that have excellent noise isolation and durability characteristics depending on the application.

Other benefits of using Micro Cellular Polyurethane (MCU) are that it can be easily tuned and optimized by changing the material’s density and it easily conforms to the spring geometry to prevent dirt and grit from becoming trapped in contact with the spring.

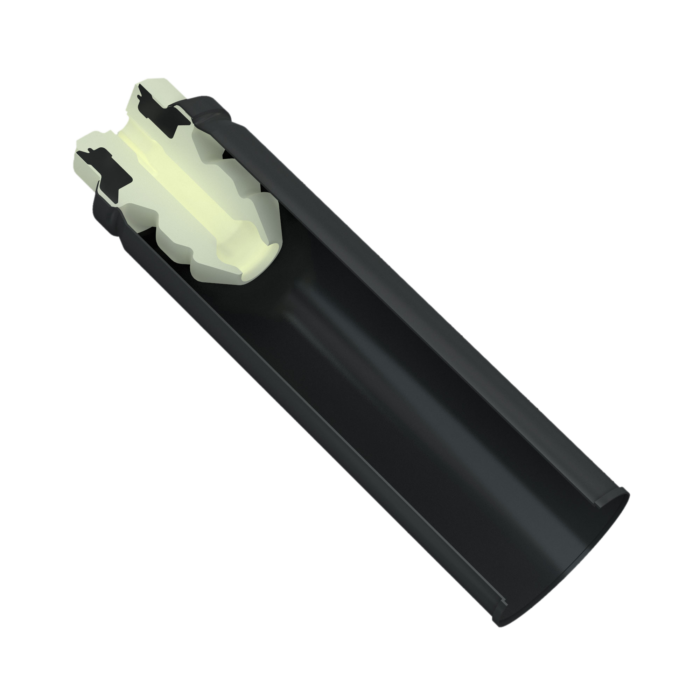

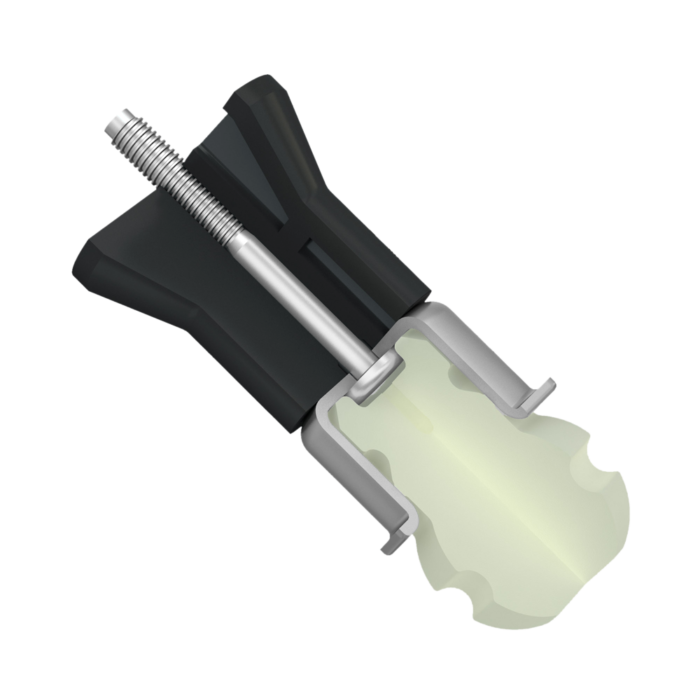

About MCU Components

Micro Cellular Urethane (MCU) components combine maximum performance, high comfort and lightweight versatility. The material provides superior abrasion, tear and chemical resistance along with high tensile strength and a low compression set. It is also resistant to automotive fluids and ozone. MCU components are used for jounce bumpers, spring aids, spring seats, bushings, top mounts, and body mounts.

more

The automotive industry needs to meet the increasing demand for lighter vehicles while integrating new components, like hybrid drives. As a result, the space available for a vehicle’s spring and isolation elements becomes smaller. Vibracoustic’s engineers work closely with vehicle manufacturers to supply a full range of materials that combine maximum performance within the ever decreasing available space.

MCU helps fulfill these requirements. Similar to a sponge, MCU absorbs energy and isolates noise, yet is strong enough to bear the weight of an entire vehicle. MCU components also offer a low weight, progressive stiffness with excellent long-term behavior when subjected to cold, heat, and the environment.

Vibracoustic offers multiple material and design options, including assembly with dust covers and saturation cups or as part of complete components like top mounts and air springs.