Light Vehicle Products | Chassis Mounts

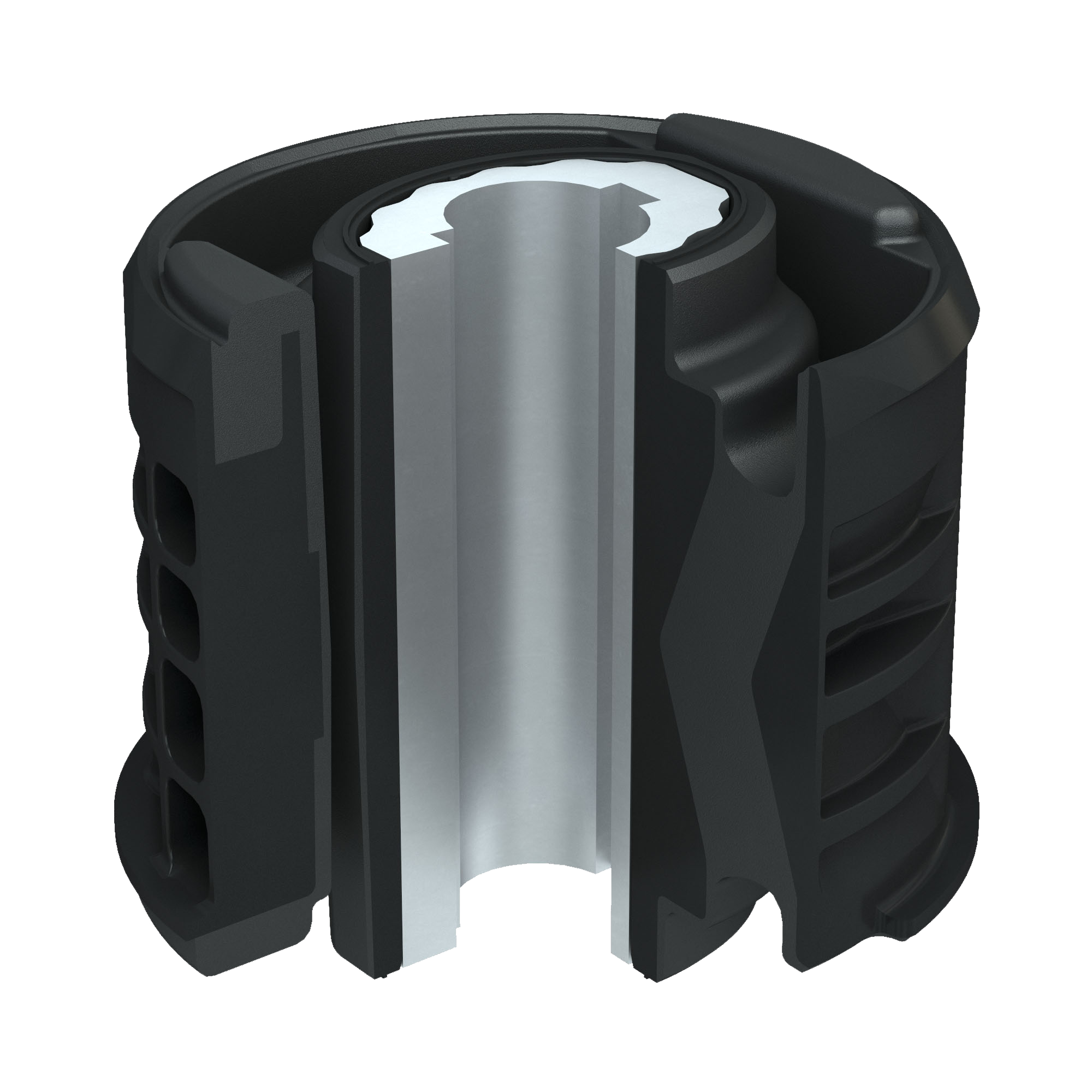

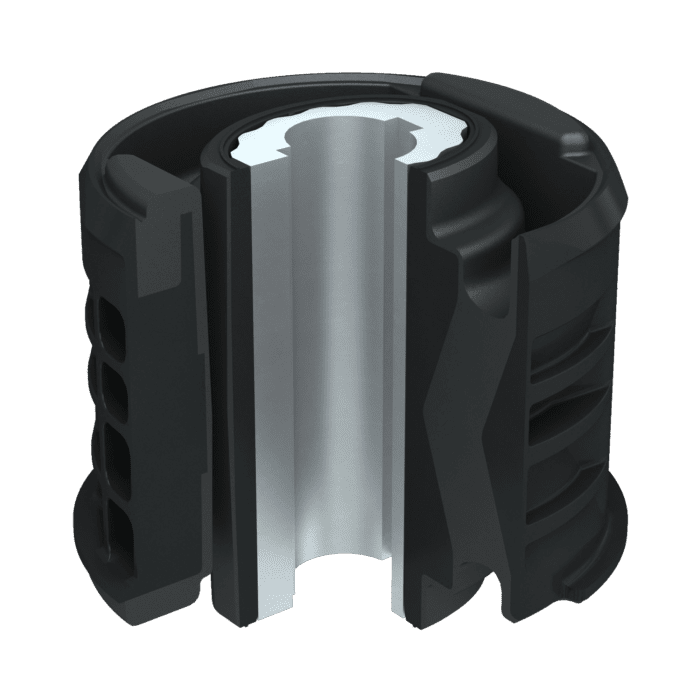

Subframe Mounts

Isolate high-frequency vibrations and noises from the road and from auxiliary devices

Isolate high-frequency vibrations and noises from the road and from auxiliary devices

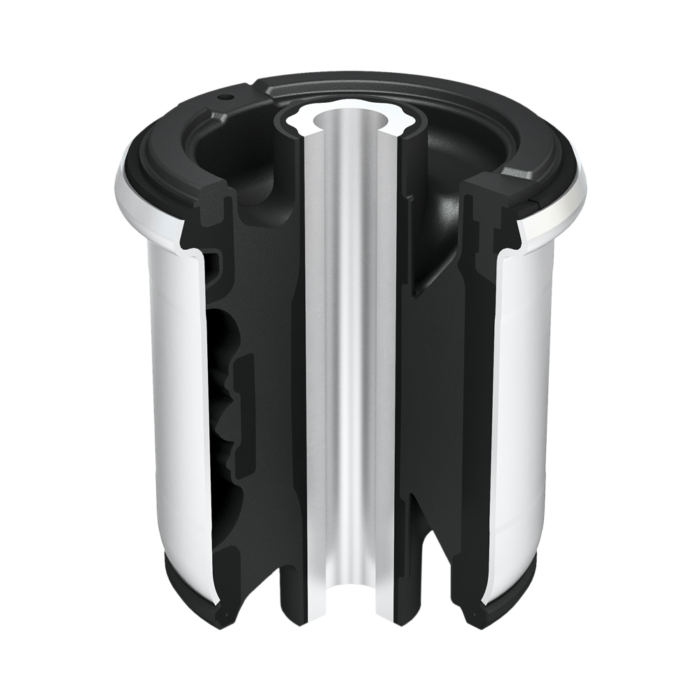

Subframe mounts must provide high stiffness in the vehicle’s transverse direction, low stiffness in the longitudinal and vertical direction, and a low dynamic hardening. Customized for specific requirements, Vibracoustic uses highly elastic and soft elastomer compounds as well as component shape designs to achieve good noise isolation and increase comfort and safety.

The outer housing can also be made of lightweight plastic, which allows geometric design flexibility as well as it helps to save weight and costs.

About Chassis Mounts

Dozens of chassis mounts control vibrations transmitted from the road surface into the chassis of the vehicle. Chassis mounts are small but important components that improve handling and safety, and reduce unwanted vibrations.

more

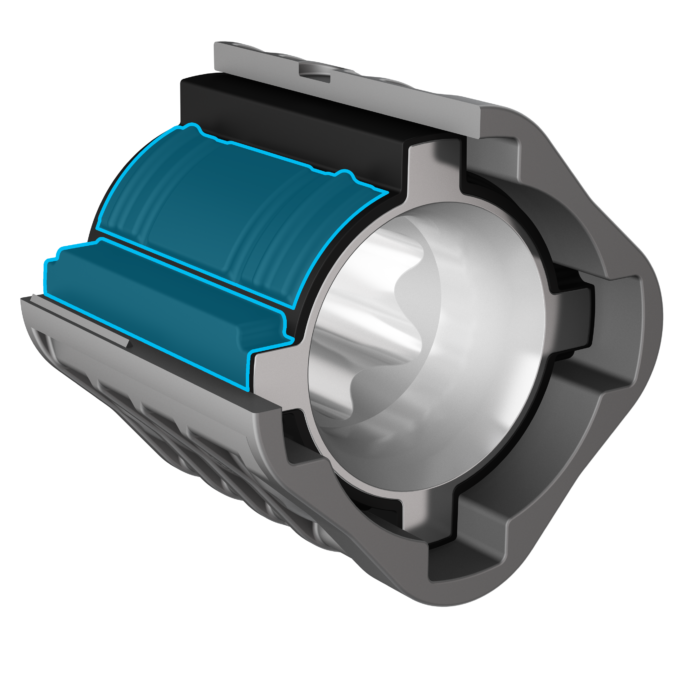

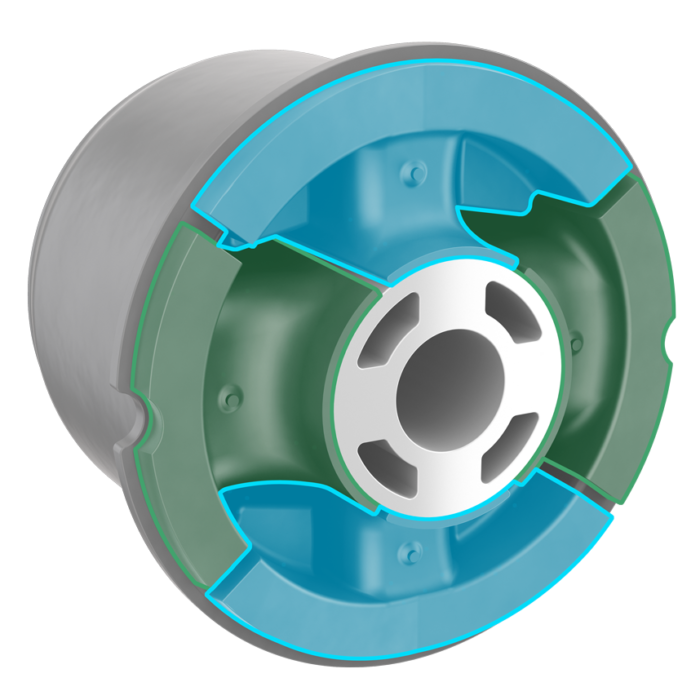

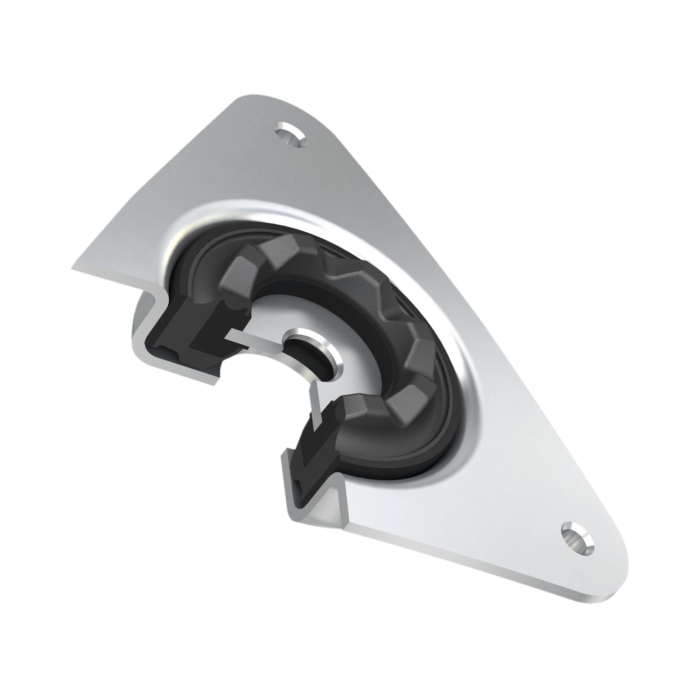

All bushings are designed to absorb loads, caused by road surface excitations, from multiple directions. The correct stiffness and damping of the bushings are essential to maximize vehicle road holding, ride and handling. Bushings must therefore be precisely tuned in line with the whole suspension system.

Minor vibrations create an unpleasant driving experience – severe ones can result in steering disturbances and body vibrations that pose serious safety risks. To reduce vibrations, vehicles have a number of chassis mounts fitted, e.g. for the transverse control arms, subframes, suspension struts and stabilizers.

The product portfolio ranges from conventional, hydro, DualRubber chassis bushings through steering column bushings, and subframe mounts to conventional and lightweight top mounts.